The Latest Inductor Manufacturer Specifications

I. Introduction

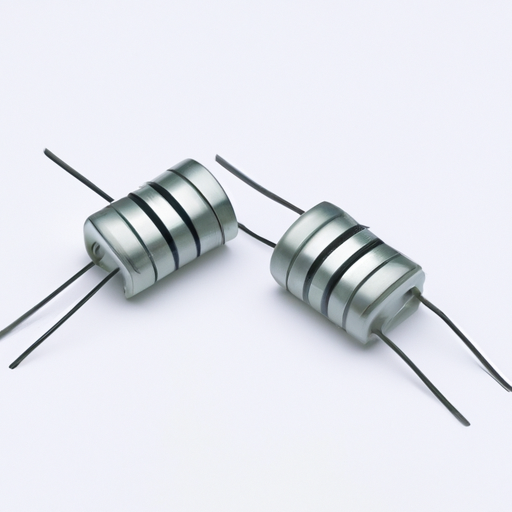

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, including power supplies, filters, and oscillators. As technology advances, the specifications of inductors evolve to meet the demands of modern applications. This article aims to provide an overview of the latest specifications from inductor manufacturers, highlighting key parameters, recent trends, and innovations that are shaping the industry.

II. Overview of Inductor Specifications

Understanding inductor specifications is essential for engineers and designers to select the right component for their applications. Here are some key parameters that define inductor specifications:

A. Key Parameters in Inductor Specifications

1. **Inductance Value**: Measured in henries (H), the inductance value indicates the inductor's ability to store energy. It is a critical factor in determining the performance of circuits, especially in filtering and energy storage applications.

2. **Current Rating**: This parameter specifies the maximum current the inductor can handle without overheating or saturating. Exceeding this rating can lead to performance degradation or failure.

3. **DC Resistance (DCR)**: DCR is the resistance of the inductor when a direct current flows through it. Lower DCR values are preferred as they minimize power loss and improve efficiency.

4. **Saturation Current**: This is the maximum current the inductor can handle before its inductance begins to drop significantly. It is crucial for applications where high current spikes may occur.

5. **Self-Resonant Frequency (SRF)**: The SRF is the frequency at which the inductor's reactance equals its resistance, causing it to behave like a resonant circuit. Understanding SRF is vital for RF applications.

6. **Temperature Coefficient**: This parameter indicates how the inductance value changes with temperature. A low temperature coefficient is desirable for stable performance across varying environmental conditions.

B. Importance of Each Parameter in Circuit Design

Each of these parameters plays a significant role in circuit design. For instance, selecting an inductor with the appropriate inductance value ensures that the circuit operates at the desired frequency. Similarly, understanding the current rating and saturation current helps prevent component failure in high-load scenarios. Overall, these specifications guide engineers in making informed decisions to optimize circuit performance.

III. Recent Trends in Inductor Manufacturing

The inductor manufacturing industry has seen several trends that influence specifications and design choices.

A. Advances in Materials

1. **Ferrite vs. Iron Powder Cores**: Ferrite cores are commonly used in high-frequency applications due to their low losses, while iron powder cores are preferred for high-current applications. Manufacturers are continually exploring new materials to enhance performance.

2. **Use of Composite Materials**: Composite materials are being utilized to improve the thermal and electrical properties of inductors. These materials can lead to better efficiency and reliability.

B. Miniaturization and Its Impact on Specifications

As electronic devices become smaller, the demand for miniaturized inductors has increased. This trend has led to the development of compact designs that maintain performance while reducing size. However, miniaturization often requires careful consideration of thermal management and current ratings.

C. Enhanced Thermal Performance

With the rise of high-power applications, manufacturers are focusing on improving the thermal performance of inductors. Enhanced cooling techniques and materials that dissipate heat more effectively are becoming standard in new designs.

D. Environmental Considerations and RoHS Compliance

Manufacturers are increasingly prioritizing environmental sustainability. Compliance with the Restriction of Hazardous Substances (RoHS) directive is now a standard requirement, pushing companies to develop eco-friendly materials and processes.

IV. Manufacturer-Specific Innovations

Several leading inductor manufacturers are at the forefront of innovation, each offering unique specifications and solutions.

A. Overview of Leading Inductor Manufacturers

1. **Murata**: Known for its high-frequency inductors, Murata has developed components that excel in RF applications, providing low loss and high performance.

2. **TDK**: TDK specializes in low-profile designs that cater to space-constrained applications. Their inductors are designed to deliver high performance without compromising on size.

3. **Vishay**: Vishay focuses on high-current inductors, offering solutions that can handle significant power loads while maintaining efficiency.

4. **Coilcraft**: Coilcraft is known for its custom solutions, allowing engineers to specify inductors tailored to their unique requirements.

B. Unique Specifications and Innovations from Each Manufacturer

Murata's High-Frequency Inductors: These inductors are designed for applications requiring high efficiency and low electromagnetic interference (EMI), making them ideal for wireless communication devices.

TDK's Low-Profile Designs: TDK's inductors are engineered for compact applications, providing high inductance values in a small footprint, which is essential for modern electronics.

Vishay's High-Current Inductors: Vishay offers inductors that can handle high currents without significant heat generation, making them suitable for power supply circuits.

Coilcraft's Custom Solutions: Coilcraft provides a range of customizable inductors, allowing engineers to specify parameters such as inductance, current rating, and size to meet specific application needs.

V. Application-Specific Inductor Specifications

Inductors are used in various applications, each requiring specific specifications to ensure optimal performance.

A. Power Electronics

1. **Inductors for DC-DC Converters**: These inductors must handle high currents and have low DCR to minimize losses. Specifications often include high saturation current ratings to accommodate load variations.

2. **Inductors for Power Supplies**: Power supply inductors require stability and efficiency, with specifications focusing on low temperature coefficients and high inductance values.

B. RF Applications

1. **Inductors for RF Filters**: RF inductors must have high SRF and low losses to ensure signal integrity. Specifications often emphasize high-frequency performance.

2. **Inductors for Oscillators**: These inductors require precise inductance values and low DCR to maintain stable oscillation frequencies.

C. Automotive Applications

1. **Inductors for Electric Vehicles**: With the rise of electric vehicles, inductors must handle high currents and provide efficient energy storage. Specifications focus on high saturation current and thermal performance.

2. **Inductors for Automotive Electronics**: Automotive inductors must meet stringent reliability standards, such as AEC-Q200, to ensure performance in harsh environments.

VI. Testing and Quality Assurance

Quality assurance is critical in the inductor manufacturing process, ensuring that components meet industry standards.

A. Industry Standards for Inductor Testing

1. **AEC-Q200 for Automotive Applications**: This standard outlines the reliability requirements for passive components used in automotive applications, ensuring safety and performance.

2. **ISO Certifications**: Many manufacturers adhere to ISO standards, which ensure consistent quality and reliability in production processes.

B. Importance of Reliability Testing

Reliability testing is essential to validate the performance of inductors under various conditions. This testing helps identify potential failure modes and ensures that components can withstand real-world applications.

C. Role of Simulation in Specification Validation

Simulation tools are increasingly used to validate inductor specifications before production. These tools allow manufacturers to model performance under different conditions, reducing the risk of design flaws.

VII. Future Directions in Inductor Technology

The future of inductor technology is promising, with several emerging trends that could reshape the industry.

A. Emerging Technologies and Their Impact on Inductor Design

1. **Wireless Power Transfer**: As wireless charging becomes more prevalent, inductors designed for efficient energy transfer will be crucial. Specifications will need to focus on high efficiency and low losses.

2. **Internet of Things (IoT) Applications**: The growing demand for IoT devices will drive the need for compact, energy-efficient inductors that can operate in diverse environments.

B. Predictions for Future Specifications and Trends

Future specifications may include even lower DCR values, higher saturation currents, and improved thermal performance. Additionally, manufacturers may explore new materials and designs to enhance efficiency and sustainability.

VIII. Conclusion

Understanding inductor specifications is vital for engineers and designers to select the right components for their applications. As technology continues to evolve, staying updated with the latest innovations from manufacturers is essential. The landscape of inductor technology is constantly changing, and being informed about these developments can lead to better design choices and improved circuit performance.

IX. References

For further reading, consider exploring manufacturer datasheets and technical documents, as well as industry publications that delve into the latest trends and specifications in inductor technology.