What are the Popular Types of Inductor Products?

I. Introduction

Inductors are fundamental components in the realm of electronics, playing a crucial role in various applications ranging from power supplies to signal processing. Defined as passive electrical components that store energy in a magnetic field when electrical current flows through them, inductors are essential for managing current and voltage in circuits. This article aims to explore the popular types of inductor products, their applications, and the factors to consider when selecting the right inductor for specific needs.

II. Basic Principles of Inductors

A. Explanation of Inductance

Inductance is the property of an inductor that quantifies its ability to store energy in a magnetic field. It is measured in henries (H) and is determined by the physical characteristics of the inductor, including the number of turns in the coil, the core material, and the geometry of the inductor.

B. How Inductors Work

When an electric current passes through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage in the opposite direction according to Lenz's Law. This property allows inductors to resist changes in current, making them valuable in filtering and energy storage applications.

C. Key Parameters of Inductors

When evaluating inductors, several key parameters must be considered:

Inductance Value: The amount of inductance, typically specified in microhenries (µH) or millihenries (mH).

Current Rating: The maximum current the inductor can handle without overheating or saturating.

Resistance: The DC resistance (DCR) of the inductor, which affects its efficiency and performance.

III. Types of Inductors

Inductors come in various types, each designed for specific applications and environments. Below are some of the most popular types of inductors.

A. Air Core Inductors

1. Definition and Construction

Air core inductors are constructed without a magnetic core, relying solely on air as the medium for magnetic field generation. They are typically made of copper wire wound into a coil.

2. Applications and Advantages

These inductors are commonly used in high-frequency applications, such as radio frequency (RF) circuits, due to their low losses and high Q factor. They are also lightweight and have a simple construction.

3. Limitations

The main limitation of air core inductors is their relatively low inductance values compared to core-based inductors, making them unsuitable for applications requiring high inductance.

B. Iron Core Inductors

1. Definition and Construction

Iron core inductors use an iron core to enhance the magnetic field generated by the coil. The core is typically made of laminated iron to reduce eddy current losses.

2. Applications and Advantages

These inductors are widely used in power applications due to their ability to achieve high inductance values in a compact size. They are effective in energy storage and filtering applications.

3. Limitations

Iron core inductors can suffer from saturation at high currents, which limits their performance. Additionally, they may introduce losses due to hysteresis and eddy currents.

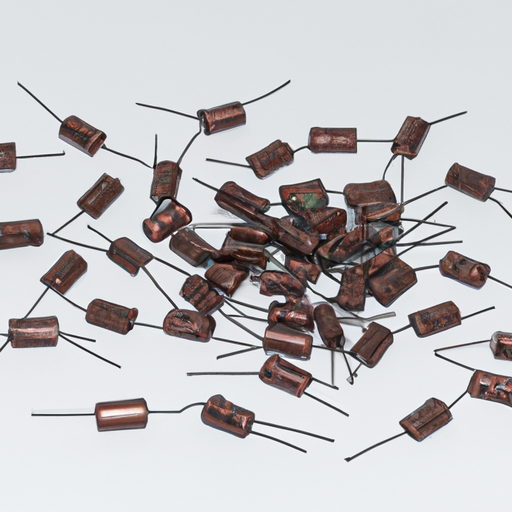

C. Ferrite Core Inductors

1. Definition and Construction

Ferrite core inductors utilize ferrite materials, which are ceramic compounds made of iron oxide and other metals. These materials have high magnetic permeability and low losses.

2. Applications and Advantages

Ferrite core inductors are commonly used in high-frequency applications, such as switch-mode power supplies and RF circuits. They offer high inductance values with minimal losses.

3. Limitations

While ferrite cores are effective, they can also saturate under high current conditions, and their performance can be affected by temperature changes.

D. Toroidal Inductors

1. Definition and Construction

Toroidal inductors are wound in a doughnut-shaped core, typically made of ferrite or iron. This design minimizes electromagnetic interference and enhances efficiency.

2. Applications and Advantages

These inductors are popular in power supplies and audio applications due to their compact size and low electromagnetic interference. They also have a high inductance-to-volume ratio.

3. Limitations

Toroidal inductors can be more expensive to manufacture and may require specialized winding techniques.

E. Choke Inductors

1. Definition and Construction

Choke inductors are designed to block high-frequency AC signals while allowing DC or low-frequency signals to pass. They can be air core or core-based.

2. Applications and Advantages

Chokes are widely used in power supply circuits to filter out noise and prevent interference. They are essential in applications requiring signal integrity.

3. Limitations

The effectiveness of choke inductors can be limited by their inductance value and current rating.

F. Variable Inductors

1. Definition and Construction

Variable inductors allow for adjustable inductance values, typically achieved through a movable core or adjustable coil turns.

2. Applications and Advantages

These inductors are used in tuning circuits, such as radio transmitters and receivers, where precise inductance adjustments are necessary.

3. Limitations

Variable inductors can be more complex and less reliable than fixed inductors, and their mechanical components may wear over time.

G. Surface Mount Inductors

1. Definition and Construction

Surface mount inductors are designed for mounting directly onto the surface of printed circuit boards (PCBs). They are typically compact and come in various shapes.

2. Applications and Advantages

These inductors are favored in modern electronics due to their small size and ease of integration into automated assembly processes.

3. Limitations

Surface mount inductors may have lower current ratings compared to their through-hole counterparts and can be more sensitive to thermal and mechanical stress.

IV. Specialized Inductor Types

A. Power Inductors

1. Definition and Construction

Power inductors are designed to handle high currents and are often used in power management applications. They typically feature a core to enhance inductance.

2. Applications and Advantages

These inductors are essential in DC-DC converters, power supplies, and energy storage systems, providing efficient energy transfer.

3. Limitations

Power inductors can be bulky and may have higher DC resistance, affecting efficiency.

B. RF Inductors

1. Definition and Construction

RF inductors are specifically designed for high-frequency applications, often featuring low resistance and high Q factors.

2. Applications and Advantages

They are used in RF amplifiers, oscillators, and filters, where performance at high frequencies is critical.

3. Limitations

RF inductors can be sensitive to temperature and may require careful design to avoid parasitic effects.

C. Common Mode Chokes

1. Definition and Construction

Common mode chokes are designed to filter out common mode noise in differential signals. They typically consist of two coils wound on a single core.

2. Applications and Advantages

These inductors are widely used in data lines and power lines to reduce electromagnetic interference and improve signal integrity.

3. Limitations

Common mode chokes can introduce additional losses and may require careful selection to match the application.

V. Factors to Consider When Choosing Inductors

When selecting an inductor for a specific application, several factors must be considered:

A. Inductance Value

The required inductance value should match the circuit's needs, ensuring proper performance.

B. Current Rating

The inductor must be able to handle the maximum current without saturating or overheating.

C. DC Resistance

Lower DC resistance is preferable for efficiency, as it reduces power losses.

D. Size and Form Factor

The physical size and shape of the inductor should fit within the design constraints of the circuit.

E. Frequency Response

The inductor's performance at the operating frequency is critical, especially in high-frequency applications.

VI. Applications of Inductors

Inductors find applications in various electronic systems, including:

A. Power Supplies

Inductors are used in switching power supplies to store energy and filter out voltage spikes.

B. Filters

Inductors are integral to low-pass, high-pass, and band-pass filters, shaping signal frequencies.

C. Oscillators

Inductors are used in oscillator circuits to create oscillating signals for various applications.

D. Transformers

Inductors are key components in transformers, enabling voltage conversion and isolation.

E. Signal Processing

Inductors help in signal conditioning and processing, ensuring signal integrity in communication systems.

VII. Future Trends in Inductor Technology

As technology advances, several trends are shaping the future of inductor technology:

A. Miniaturization and Integration

The demand for smaller, more efficient inductors is driving innovations in design and materials, leading to compact solutions for modern electronics.

B. Advances in Materials

New materials, such as nanocrystalline and amorphous alloys, are being explored to enhance performance and reduce losses.

C. Smart Inductors and IoT Applications

The integration of inductors with smart technologies and IoT applications is paving the way for intelligent energy management and enhanced functionality.

VIII. Conclusion

Inductors are vital components in electronic circuits, serving various functions from energy storage to signal filtering. Understanding the different types of inductors, their applications, and the factors influencing their selection is essential for engineers and designers. As technology continues to evolve, the future of inductor technology promises exciting advancements that will further enhance their capabilities and applications.

IX. References

For further reading on inductors and their applications, consider the following sources:

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Inductor Design and Applications" by John L. H. Hsu

- IEEE Journals and Conference Papers on Inductor Technology

This comprehensive overview of inductor products provides a solid foundation for understanding their importance and applications in modern electronics.