What are the Mainstream Models of Adjustable Inductors?

I. Introduction

A. Definition of Adjustable Inductors

Adjustable inductors are components in electronic circuits that allow for the modification of inductance values. This adjustability is crucial for tuning circuits, filtering signals, and managing power in various applications. By altering the inductance, engineers can optimize circuit performance for specific requirements.

B. Importance of Adjustable Inductors in Electronics

In the realm of electronics, adjustable inductors play a vital role in enhancing the functionality and efficiency of devices. They are commonly used in radio frequency (RF) applications, power supplies, and audio equipment, where precise control over inductance can significantly impact performance. Their ability to adapt to changing conditions makes them indispensable in modern electronic design.

C. Overview of the Article

This article will explore the basics of inductance, the various types of adjustable inductors, mainstream models, their applications, and future trends. By the end, readers will have a comprehensive understanding of adjustable inductors and their significance in electronic systems.

II. Basics of Inductance

A. Explanation of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This phenomenon is known as self-induction.

B. Role of Inductors in Circuits

Inductors are used in various applications, including filtering, energy storage, and signal processing. They can store energy in a magnetic field when current flows through them, releasing it when the current decreases. This ability makes inductors essential in power supplies, oscillators, and RF circuits.

C. Types of Inductors

Inductors can be classified into several types, including fixed inductors, variable inductors, tapped inductors, air-core inductors, and ferrite-core inductors. Each type has unique characteristics and applications, making them suitable for different electronic designs.

III. Types of Adjustable Inductors

A. Variable Inductors

1. Definition and Functionality

Variable inductors allow users to adjust the inductance value manually. This is typically achieved through a mechanical adjustment, such as a knob or slider, which changes the number of turns in the coil or the core's position.

2. Common Applications

Variable inductors are widely used in tuning circuits, such as radio receivers, where precise inductance adjustments are necessary to select specific frequencies.

B. Tapped Inductors

1. Definition and Functionality

Tapped inductors have multiple connection points along the coil, allowing users to select different inductance values without needing to adjust the physical structure of the inductor.

2. Common Applications

These inductors are often used in audio equipment and RF applications, where different inductance values are required for various operational modes.

C. Air-Core Inductors

1. Definition and Functionality

Air-core inductors are coils of wire without a magnetic core. They are lightweight and have low losses, making them suitable for high-frequency applications.

2. Common Applications

Air-core inductors are commonly used in RF circuits, antennas, and applications where low inductance values are required.

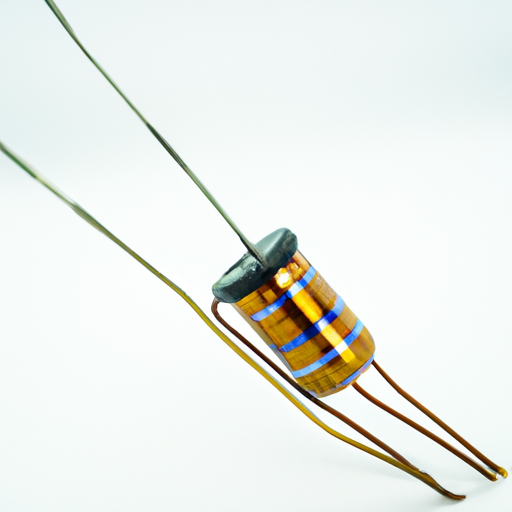

D. Ferrite-Core Inductors

1. Definition and Functionality

Ferrite-core inductors use a ferrite material as the core, which enhances inductance and reduces losses at high frequencies. They are more compact than air-core inductors and can handle higher power levels.

2. Common Applications

Ferrite-core inductors are widely used in power supplies, transformers, and RF applications, where efficiency and size are critical.

IV. Mainstream Models of Adjustable Inductors

A. Variable Inductors

1. Description of Popular Models

Popular variable inductor models include the variable air-core inductor and the variable ferrite-core inductor. These models are designed for easy adjustment and are often used in educational settings and prototype development.

2. Specifications and Features

Specifications typically include inductance range, maximum current rating, and physical dimensions. Features may include a locking mechanism to maintain the set inductance value.

3. Use Cases

These inductors are ideal for applications requiring frequent tuning, such as in amateur radio setups and experimental circuits.

B. Tapped Inductors

1. Description of Popular Models

Tapped inductors like the Miniature Tapped Inductor and the High-Power Tapped Inductor are commonly used in audio and RF applications.

2. Specifications and Features

Specifications include the number of taps, inductance values at each tap, and power handling capabilities. Features may include compact designs and high-quality materials for durability.

3. Use Cases

Tapped inductors are often used in audio crossovers and RF amplifiers, where different inductance values are needed for various frequency ranges.

C. Air-Core Inductors

1. Description of Popular Models

Popular air-core inductor models include the Air-Core RF Inductor and the High-Frequency Air-Core Inductor, designed for minimal losses at high frequencies.

2. Specifications and Features

Specifications typically include inductance values, wire gauge, and physical dimensions. Features may include high-temperature resistance and low parasitic capacitance.

3. Use Cases

These inductors are commonly used in RF applications, such as antennas and oscillators, where low losses are critical.

D. Ferrite-Core Inductors

1. Description of Popular Models

Ferrite-core inductors like the Ferrite Toroidal Inductor and the Ferrite Core Power Inductor are widely used in power electronics.

2. Specifications and Features

Specifications include inductance values, current ratings, and core material properties. Features may include compact designs and high efficiency.

3. Use Cases

Ferrite-core inductors are used in power supplies, DC-DC converters, and RF applications, where efficiency and size are essential.

V. Comparison of Adjustable Inductor Models

A. Performance Metrics

1. Inductance Range

Different models offer varying inductance ranges, with variable inductors typically providing the widest range for tuning applications.

2. Quality Factor (Q)

The quality factor indicates the efficiency of the inductor. Air-core inductors generally have higher Q values than ferrite-core inductors due to lower losses.

3. Power Handling

Ferrite-core inductors can handle higher power levels compared to air-core inductors, making them suitable for power applications.

B. Advantages and Disadvantages

1. Cost Considerations

Variable inductors tend to be more expensive due to their adjustability, while air-core inductors are often more affordable.

2. Size and Form Factor

Air-core inductors are typically larger than ferrite-core inductors, which can be a consideration in compact designs.

3. Temperature Stability

Ferrite-core inductors generally offer better temperature stability compared to air-core inductors, making them more reliable in varying conditions.

VI. Applications of Adjustable Inductors

A. RF and Communication Systems

Adjustable inductors are crucial in RF applications, allowing for precise tuning of frequencies in transmitters and receivers.

B. Power Electronics

In power supplies and converters, adjustable inductors help manage energy flow and improve efficiency.

C. Audio Equipment

In audio systems, adjustable inductors are used in crossovers and equalizers to tailor sound quality.

D. Educational and Experimental Use

Adjustable inductors are often used in educational settings for experiments and demonstrations, allowing students to explore inductance concepts hands-on.

VII. Future Trends in Adjustable Inductors

A. Technological Advancements

Advancements in materials and manufacturing techniques are leading to more efficient and compact adjustable inductors.

B. Integration with Smart Technologies

As electronics become smarter, adjustable inductors may be integrated with digital controls for automated tuning and optimization.

C. Sustainability and Eco-Friendly Designs

The push for sustainability is driving the development of eco-friendly inductors, using recyclable materials and energy-efficient designs.

VIII. Conclusion

A. Summary of Key Points

Adjustable inductors are essential components in modern electronics, offering flexibility and precision in various applications. Understanding the different types and models can help engineers and designers make informed choices.

B. Importance of Choosing the Right Adjustable Inductor

Selecting the appropriate adjustable inductor is crucial for optimizing circuit performance and ensuring reliability in applications.

C. Final Thoughts on the Future of Adjustable Inductors

As technology continues to evolve, adjustable inductors will play a significant role in shaping the future of electronics, driving innovation and efficiency in countless applications.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Data Sheets

- Coilcraft

- Vishay Intertechnology

This comprehensive overview of adjustable inductors highlights their importance, types, mainstream models, and future trends, providing valuable insights for anyone interested in electronics.