Common Production Processes for Resistor Packaging

I. Introduction

Resistor packaging is a critical aspect of electronics manufacturing, serving as the protective and functional enclosure for resistors used in various electronic devices. Resistors are fundamental components that regulate current flow, and their packaging ensures reliability, performance, and longevity. This article explores the common production processes involved in resistor packaging, highlighting the types of resistors, materials used, manufacturing techniques, and future trends in the industry.

II. Types of Resistors

Resistors come in various types, each with unique characteristics and packaging requirements:

A. Fixed Resistors

Fixed resistors have a constant resistance value and are widely used in electronic circuits. Their packaging must ensure stability and reliability under varying environmental conditions.

B. Variable Resistors

Variable resistors, such as potentiometers, allow users to adjust resistance values. Their packaging often includes mechanisms for easy adjustment while maintaining electrical integrity.

C. Specialty Resistors

Specialty resistors, including thermistors and photoresistors, are designed for specific applications. Their packaging must accommodate unique operational requirements, such as temperature sensitivity or light exposure.

D. Overview of Packaging Needs for Each Type

Each type of resistor has distinct packaging needs based on its function, environmental exposure, and application. Understanding these needs is crucial for selecting appropriate materials and manufacturing processes.

III. Materials Used in Resistor Packaging

The choice of materials for resistor packaging significantly impacts performance and durability. Key materials include:

A. Conductive Materials

1. **Metal Films**: Used in thin film resistors, metal films provide high precision and stability.

2. **Carbon Composition**: Common in carbon resistors, this material offers good performance at a lower cost.

B. Insulating Materials

1. **Epoxy Resins**: These resins are widely used for their excellent insulating properties and resistance to environmental factors.

2. **Ceramic Materials**: Ceramics are often used in high-temperature applications due to their thermal stability.

C. Protective Coatings

1. **Conformal Coatings**: These coatings protect resistors from moisture and contaminants, enhancing reliability.

2. **Heat Shrink Tubing**: Used for additional insulation and protection, heat shrink tubing is applied to resistors to prevent short circuits.

IV. Common Production Processes

The production of resistor packaging involves several key processes:

A. Design and Prototyping

1. **Electrical Specifications**: Engineers define the electrical characteristics required for the resistor, including resistance value, tolerance, and power rating.

2. **Mechanical Design**: The physical dimensions and layout of the resistor are designed to ensure compatibility with electronic circuits.

B. Material Selection

1. **Criteria for Material Selection**: Factors such as electrical performance, thermal stability, and environmental resistance guide material selection.

2. **Sourcing and Quality Control**: Manufacturers must source high-quality materials and implement stringent quality control measures to ensure consistency.

C. Manufacturing Processes

1. **Film Resistor Production**

- **Thin Film Technology**: Involves depositing a thin layer of resistive material onto a substrate, allowing for precise resistance values.

- **Thick Film Technology**: Utilizes a thicker layer of resistive paste, suitable for high-power applications.

2. **Wirewound Resistor Production**: Involves winding a resistive wire around a core, providing high power ratings and stability.

3. **Carbon Composition Resistor Production**: Involves mixing carbon with a binder to create a resistive material, which is then shaped and cured.

D. Assembly Techniques

1. **Automated Assembly**: Modern manufacturing often employs automated systems for efficient and precise assembly of resistors.

2. **Manual Assembly**: In some cases, manual assembly is necessary for specialized or low-volume production.

E. Testing and Quality Assurance

1. **Electrical Testing**: Each resistor undergoes electrical testing to verify its resistance value and performance.

2. **Environmental Testing**: Resistors are subjected to environmental conditions, such as humidity and temperature extremes, to ensure reliability.

3. **Reliability Testing**: Long-term testing assesses the durability and lifespan of resistors under operational conditions.

V. Packaging Techniques

The packaging of resistors is crucial for their integration into electronic devices. Common techniques include:

A. Surface Mount Technology (SMT)

1. **Advantages of SMT Packaging**: SMT allows for smaller component sizes, higher circuit density, and automated assembly, making it ideal for modern electronics.

2. **Common SMT Packages**: Resistors are often packaged in small, flat formats, such as 0402 or 0603 sizes, suitable for surface mounting.

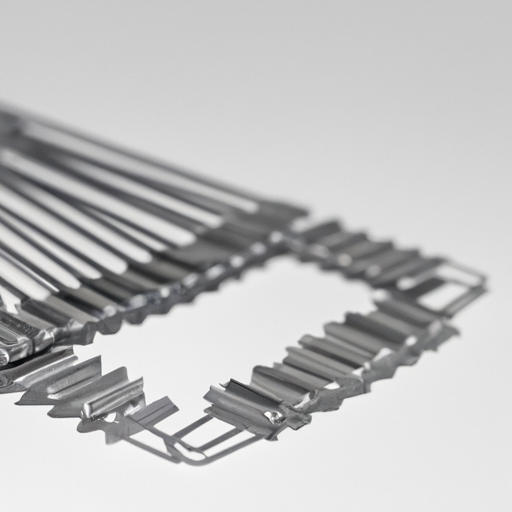

B. Through-Hole Technology (THT)

1. **Advantages of THT Packaging**: THT provides robust mechanical connections and is often used in applications requiring high power or durability.

2. **Common THT Packages**: Resistors in THT are typically cylindrical or rectangular, with leads that pass through the circuit board.

C. Hybrid Packaging

1. **Combining SMT and THT**: Hybrid packaging leverages the benefits of both SMT and THT, allowing for versatile designs.

2. **Applications of Hybrid Packaging**: This approach is often used in complex electronic systems where space and performance are critical.

VI. Environmental Considerations

As the electronics industry evolves, environmental considerations become increasingly important:

A. RoHS Compliance

Manufacturers must adhere to the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electronic products.

B. Sustainable Materials and Processes

The industry is moving towards sustainable materials and processes, including the use of recyclable packaging and eco-friendly manufacturing techniques.

C. End-of-Life Considerations for Resistors

Designing resistors for easy disassembly and recycling at the end of their life cycle is becoming a priority for manufacturers.

VII. Future Trends in Resistor Packaging

The future of resistor packaging is shaped by technological advancements and market demands:

A. Miniaturization and High-Density Packaging

As electronic devices become smaller and more powerful, the demand for miniaturized resistors and high-density packaging solutions is increasing.

B. Smart Resistors and IoT Integration

The rise of the Internet of Things (IoT) is driving the development of smart resistors that can communicate data and adapt to changing conditions.

C. Innovations in Materials and Manufacturing Techniques

Ongoing research is focused on developing new materials and manufacturing techniques that enhance performance, reduce costs, and improve sustainability.

VIII. Conclusion

In summary, resistor packaging is a vital component of electronics manufacturing, encompassing various processes from design to testing. Understanding the types of resistors, materials used, and production techniques is essential for ensuring reliability and performance in electronic devices. As the industry continues to evolve, embracing sustainability and innovation will be crucial for meeting future demands. The continuous improvement in resistor packaging will play a significant role in shaping the future of electronics, ensuring that devices remain efficient, reliable, and environmentally friendly.

IX. References

A comprehensive list of academic journals, industry reports, and manufacturer guidelines can provide further insights into the intricacies of resistor packaging and its evolving landscape.