The Production Process of Mainstream RF Inductors

I. Introduction

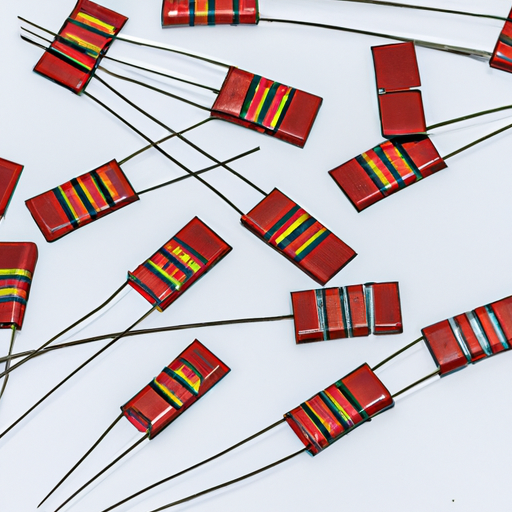

A. Definition of RF Inductors

Radio Frequency (RF) inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are essential in various applications, particularly in RF circuits, where they help filter signals, manage power, and ensure efficient communication.

B. Importance of RF Inductors in Modern Electronics

In today's fast-paced technological landscape, RF inductors play a crucial role in enabling wireless communication, signal processing, and power management. They are integral to devices such as smartphones, radios, and satellite systems, where they help maintain signal integrity and reduce noise.

C. Overview of the Production Process

The production of RF inductors involves several stages, from design and prototyping to testing and quality assurance. Understanding this process is vital for manufacturers aiming to produce high-quality inductors that meet the demands of modern electronics.

II. Understanding RF Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. This magnetic field can store energy, which is the fundamental principle behind inductors. The inductance value, measured in henries (H), depends on factors such as the number of turns in the coil, the core material, and the coil's geometry.

B. Types of RF Inductors

1. **Air-Core Inductors**: These inductors use air as the core material, making them lightweight and suitable for high-frequency applications. They are often used in RF circuits where low losses are critical.

2. **Ferrite-Core Inductors**: Ferrite cores are made from magnetic ceramic materials that enhance inductance and reduce losses. These inductors are commonly used in power supplies and RF applications due to their efficiency.

3. **Laminated Inductors**: Laminated inductors consist of multiple layers of magnetic material, which help reduce eddy currents and improve performance. They are often used in high-power applications.

C. Applications of RF Inductors

1. **Communication Systems**: RF inductors are vital in transmitters and receivers, where they filter and amplify signals to ensure clear communication.

2. **Signal Processing**: In signal processing circuits, RF inductors help manage frequency response and improve signal quality.

3. **Power Management**: RF inductors are used in power supplies to regulate voltage and current, ensuring efficient energy distribution.

III. Raw Materials Used in RF Inductor Production

A. Conductive Materials

1. **Copper**: Copper is the most commonly used conductive material for winding coils due to its excellent electrical conductivity and thermal properties.

2. **Aluminum**: Aluminum is lighter and less expensive than copper, making it a viable alternative in certain applications, although it has lower conductivity.

B. Magnetic Materials

1. **Ferrite**: Ferrite is a ceramic material made from iron oxide and other metal oxides. It is widely used in RF inductors due to its high magnetic permeability and low losses at high frequencies.

2. **Iron Powder**: Iron powder is used in some inductors to enhance magnetic properties, particularly in applications requiring high inductance values.

C. Insulating Materials

1. **Epoxy Resins**: Epoxy resins are commonly used for encapsulating inductors, providing mechanical strength and environmental protection.

2. **Polyimide Films**: These films are used for insulation due to their excellent thermal stability and electrical properties.

IV. The Production Process

A. Design and Prototyping

1. **Simulation and Modeling**: The production process begins with the design phase, where engineers use simulation software to model the inductor's performance. This step helps optimize parameters such as inductance, resistance, and size.

2. **Prototyping Techniques**: Once the design is finalized, prototypes are created using rapid prototyping techniques. This allows for testing and validation before mass production.

B. Coil Winding

1. **Manual vs. Automated Winding**: Coil winding can be done manually or through automated machines. Automated winding is preferred for mass production due to its speed and precision.

2. **Winding Techniques**: Various winding techniques, such as layer winding and bifilar winding, are employed to achieve the desired inductance and minimize losses.

C. Core Assembly

1. **Core Selection**: The choice of core material is critical for the inductor's performance. Engineers select the appropriate core based on the application's frequency and power requirements.

2. **Core Preparation**: The core is prepared by cutting and shaping it to fit the coil. This step may involve processes such as grinding or machining.

D. Soldering and Connections

1. **Soldering Techniques**: After winding the coil and assembling the core, connections are made using soldering techniques. This step ensures reliable electrical connections between the inductor and the circuit.

2. **Quality Control Measures**: Quality control is essential during soldering to prevent defects. Techniques such as visual inspection and automated soldering machines are employed to ensure high standards.

E. Encapsulation and Insulation

1. **Types of Encapsulation**: Encapsulation protects the inductor from environmental factors. Common methods include potting, where the inductor is immersed in a protective resin, and encapsulation in plastic housings.

2. **Insulation Techniques**: Insulation is crucial to prevent short circuits and ensure safety. Techniques such as applying insulating coatings or using insulated wire are commonly used.

F. Testing and Quality Assurance

1. **Electrical Testing**: Each inductor undergoes electrical testing to verify its performance characteristics, including inductance, resistance, and quality factor (Q).

2. **Environmental Testing**: Inductors are subjected to environmental tests to ensure they can withstand temperature variations, humidity, and other conditions.

3. **Compliance with Standards**: Manufacturers must ensure that their inductors comply with industry standards, such as those set by the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

V. Challenges in RF Inductor Production

A. Material Limitations

The availability and cost of raw materials can impact production. Manufacturers must balance performance with cost-effectiveness, especially in competitive markets.

B. Precision and Tolerances

Achieving precise tolerances is critical in RF inductor production. Even minor deviations can affect performance, making quality control essential throughout the manufacturing process.

C. Cost Management

Managing production costs while maintaining quality is a constant challenge. Manufacturers must optimize processes and materials to remain competitive.

D. Environmental Considerations

As environmental regulations become stricter, manufacturers must consider the environmental impact of their production processes and materials. This includes waste management and the use of sustainable materials.

VI. Future Trends in RF Inductor Production

A. Advances in Materials Science

Research into new materials, such as nanomaterials and composites, is paving the way for more efficient and compact RF inductors. These materials can enhance performance while reducing size and weight.

B. Automation and Industry 4.0

The integration of automation and smart manufacturing technologies is transforming the production process. Industry 4.0 enables real-time monitoring and data analysis, improving efficiency and reducing errors.

C. Miniaturization and High-Frequency Applications

As electronic devices become smaller and more powerful, the demand for miniaturized RF inductors is increasing. Manufacturers are focusing on developing inductors that can operate effectively at higher frequencies without compromising performance.

VII. Conclusion

A. Summary of the Production Process

The production of mainstream RF inductors involves a complex process that includes design, material selection, coil winding, core assembly, soldering, encapsulation, and rigorous testing. Each step is crucial to ensure the final product meets the high standards required in modern electronics.

B. The Role of RF Inductors in Future Technologies

As technology continues to evolve, RF inductors will remain a vital component in various applications, from communication systems to power management. Their ability to efficiently manage signals and energy will be essential in the development of future technologies.

C. Final Thoughts on the Importance of Quality in Production

Quality is paramount in the production of RF inductors. Manufacturers must prioritize precision, material selection, and testing to ensure their products meet the demands of an increasingly complex electronic landscape. By focusing on quality, manufacturers can contribute to the advancement of technology and the enhancement of user experiences.

VIII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Reports

- Market Research Reports on RF Components

- Industry Analysis by Electronics Manufacturers Association

C. Manufacturer Guidelines

- Technical Specifications from Leading RF Inductor Manufacturers

- Best Practices for Inductor Design and Production

This comprehensive overview of the production process of mainstream RF inductors highlights the intricate steps involved and the importance of quality in manufacturing. As technology advances, the role of RF inductors will continue to be pivotal in shaping the future of electronics.