Current Situation of the Magnetic Inductor Industry

I. Introduction

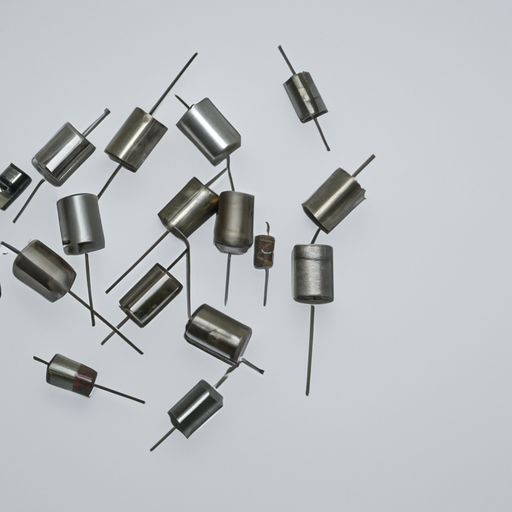

A. Definition of Magnetic Inductors

Magnetic inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are essential in various applications, including power supplies, filters, and energy storage systems. Inductors are characterized by their inductance, which is the ability to store energy in a magnetic field, and they play a crucial role in managing electrical energy in circuits.

B. Importance of Magnetic Inductors in Modern Technology

In today's technology-driven world, magnetic inductors are integral to the functioning of numerous devices. From consumer electronics to automotive systems, inductors help regulate power, filter signals, and ensure efficient energy transfer. As the demand for more compact and efficient electronic devices grows, the role of magnetic inductors becomes increasingly significant.

C. Purpose of the Report

This report aims to provide an in-depth analysis of the current situation of the magnetic inductor industry, exploring its historical context, market dynamics, technological advancements, applications, challenges, and future outlook.

II. Overview of the Magnetic Inductor Industry

A. Historical Context

1. Evolution of Magnetic Inductors

The concept of inductance dates back to the early 19th century, with Michael Faraday's experiments leading to the understanding of electromagnetic induction. Over the decades, magnetic inductors have evolved from simple wire coils to sophisticated components made from advanced materials and designs.

2. Key Milestones in the Industry

The development of ferrite materials in the mid-20th century marked a significant milestone, allowing for the creation of smaller and more efficient inductors. The rise of consumer electronics in the 1980s and 1990s further propelled the industry, as the demand for compact and efficient components surged.

B. Current Market Size and Growth Trends

1. Global Market Overview

As of 2023, the global magnetic inductor market is valued at approximately $5 billion, with projections indicating a compound annual growth rate (CAGR) of around 6% over the next five years. This growth is driven by the increasing demand for electronic devices and the rise of electric vehicles (EVs).

2. Regional Market Insights

North America and Asia-Pacific are the leading regions in the magnetic inductor market. Asia-Pacific, particularly China, is a manufacturing hub for electronic components, contributing significantly to the global supply chain. Meanwhile, North America is witnessing growth due to advancements in automotive technology and consumer electronics.

C. Key Players in the Industry

1. Major Manufacturers

The magnetic inductor industry is dominated by several key players, including:

Murata Manufacturing Co., Ltd.: A leading manufacturer known for its high-quality inductors used in various applications.

TDK Corporation: Offers a wide range of inductors, including power inductors and RF inductors.

Vishay Intertechnology, Inc.: Provides a diverse portfolio of inductors for different industries.

2. Emerging Companies

In addition to established players, several emerging companies are making their mark in the industry, focusing on innovative designs and materials to meet the evolving demands of the market.

III. Technological Advancements

A. Innovations in Magnetic Inductor Design

1. Materials Used

Recent advancements in materials science have led to the development of new magnetic materials, such as nanocrystalline and amorphous alloys, which enhance the performance of inductors. These materials offer improved efficiency, reduced losses, and better thermal management.

2. Miniaturization and Efficiency Improvements

The trend towards miniaturization in electronics has driven the design of smaller inductors without compromising performance. Innovations in manufacturing techniques, such as multilayer and integrated inductors, have enabled the production of compact components that meet the demands of modern devices.

B. Impact of Industry 4.0 and IoT

1. Smart Inductors

The rise of Industry 4.0 and the Internet of Things (IoT) has led to the development of smart inductors equipped with sensors and communication capabilities. These inductors can monitor performance in real-time, enabling predictive maintenance and enhancing overall system efficiency.

2. Integration with Other Technologies

Magnetic inductors are increasingly being integrated with other technologies, such as power electronics and energy storage systems, to create more efficient and versatile solutions for various applications.

IV. Applications of Magnetic Inductors

A. Consumer Electronics

1. Smartphones and Tablets

Magnetic inductors are crucial in smartphones and tablets, where they are used in power management circuits, audio systems, and RF applications. The demand for high-performance inductors in these devices continues to grow as manufacturers strive for better battery life and enhanced functionality.

2. Wearable Devices

The wearable technology market is expanding rapidly, with magnetic inductors playing a vital role in powering devices like smartwatches and fitness trackers. The need for compact and efficient inductors is paramount in this sector.

B. Automotive Industry

1. Electric Vehicles (EVs)

The shift towards electric vehicles has significantly impacted the magnetic inductor industry. Inductors are essential in EV powertrains, battery management systems, and charging infrastructure, contributing to the overall efficiency and performance of electric vehicles.

2. Advanced Driver-Assistance Systems (ADAS)

Magnetic inductors are also integral to ADAS, where they help manage power and signal processing for features like adaptive cruise control and lane-keeping assistance. The growing focus on safety and automation in vehicles is driving demand for high-quality inductors.

C. Industrial Applications

1. Power Supplies

In industrial settings, magnetic inductors are used in power supply units to regulate voltage and current. Their reliability and efficiency are critical for maintaining the performance of industrial machinery.

2. Renewable Energy Systems

As the world shifts towards renewable energy sources, magnetic inductors are increasingly used in solar inverters and wind turbine systems. They play a crucial role in converting and managing energy from these sources.

V. Challenges Facing the Industry

A. Supply Chain Disruptions

1. Raw Material Shortages

The magnetic inductor industry faces challenges related to the availability of raw materials, particularly rare earth elements and specialized alloys. Supply chain disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have led to increased costs and delays.

2. Geopolitical Factors

Geopolitical factors, such as trade restrictions and tariffs, can impact the supply chain and pricing of magnetic inductors. Companies must navigate these challenges to maintain competitiveness in the market.

B. Environmental Concerns

1. Sustainability of Materials

As environmental awareness grows, the industry faces pressure to adopt sustainable practices. The sourcing of materials used in inductors must consider environmental impact, leading to a push for more eco-friendly alternatives.

2. Recycling and Waste Management

The disposal of electronic waste, including inductors, poses environmental challenges. The industry must develop effective recycling methods to minimize waste and promote sustainability.

C. Competition and Market Saturation

1. Price Wars

Intense competition among manufacturers has led to price wars, impacting profit margins. Companies must find ways to differentiate their products and maintain profitability in a saturated market.

2. Innovation Race

The rapid pace of technological advancements necessitates continuous innovation. Companies must invest in research and development to stay ahead of competitors and meet the evolving needs of customers.

VI. Future Outlook

A. Market Projections

1. Expected Growth Rates

The magnetic inductor market is expected to continue its growth trajectory, with projections indicating a CAGR of around 6% through 2028. This growth will be driven by advancements in technology and increasing demand across various sectors.

2. Emerging Markets

Emerging markets, particularly in Asia and Africa, present significant opportunities for growth. As these regions develop their electronics industries, the demand for magnetic inductors is likely to rise.

B. Potential Innovations

1. Next-Generation Materials

Future innovations may include the development of next-generation materials that enhance the performance and efficiency of inductors. Research into superconducting materials and advanced composites could lead to breakthroughs in the industry.

2. Enhanced Performance Metrics

As technology evolves, the performance metrics of magnetic inductors will need to improve. This includes higher inductance values, lower losses, and better thermal management to meet the demands of modern applications.

C. Strategic Recommendations for Industry Players

1. Investment in R&D

To remain competitive, companies should prioritize investment in research and development. This will enable them to innovate and develop new products that meet the changing needs of the market.

2. Collaboration and Partnerships

Forming strategic partnerships with other companies and research institutions can foster innovation and enhance product offerings. Collaboration can also help address supply chain challenges and promote sustainability.

VII. Conclusion

A. Summary of Key Findings

The magnetic inductor industry is at a pivotal point, characterized by significant growth, technological advancements, and increasing demand across various applications. However, challenges such as supply chain disruptions and environmental concerns must be addressed to ensure sustainable growth.

B. The Importance of Adaptation and Innovation

As the industry evolves, companies must adapt to changing market dynamics and invest in innovation to remain competitive. Embracing new technologies and sustainable practices will be crucial for long-term success.

C. Final Thoughts on the Future of the Magnetic Inductor Industry

The future of the magnetic inductor industry looks promising, with ample opportunities for growth and innovation. By navigating challenges and leveraging advancements in technology, industry players can position themselves for success in this dynamic market.

VIII. References

A. Academic Journals

- Journal of Applied Physics

- IEEE Transactions on Power Electronics

B. Industry Reports

- MarketsandMarkets: Magnetic Inductor Market Report

- Grand View Research: Inductor Market Analysis

C. Market Research Publications

- Research and Markets: Global Magnetic Inductor Market Trends

- Technavio: Magnetic Inductor Market Forecast 2023-2028

---

This blog post provides a comprehensive overview of the current situation of the magnetic inductor industry, highlighting its significance, challenges, and future prospects. Each section is designed to inform readers about the complexities and dynamics of this essential component in modern technology.