What are the Main Application Directions of Inductor Factories?

I. Introduction

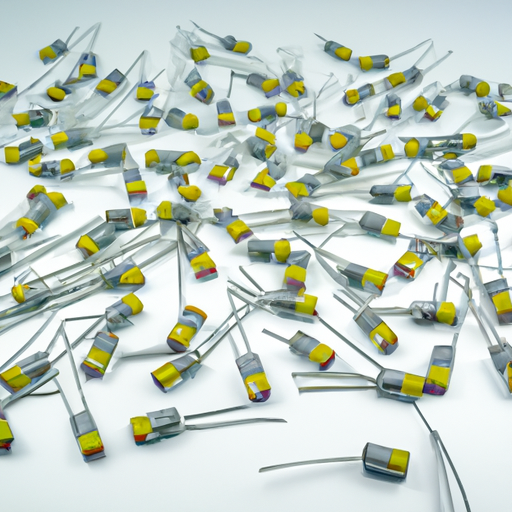

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As the backbone of many electronic systems, inductors are essential in ensuring the efficient operation of devices ranging from simple household appliances to complex industrial machinery. Inductor factories are pivotal in the electronics industry, providing the necessary components that enable technological advancements and innovations.

II. Types of Inductors

Inductors come in various types, each designed for specific applications and performance characteristics. Understanding these types is essential for recognizing their diverse applications.

A. Air-core Inductors

Air-core inductors are made without a magnetic core, relying solely on the air surrounding the coil to create inductance. They are typically used in high-frequency applications due to their low losses and high Q-factor, making them ideal for RF circuits and signal processing.

B. Iron-core Inductors

Iron-core inductors utilize a ferromagnetic core to enhance inductance. These inductors are commonly found in power applications, where they can handle higher currents and provide better energy storage capabilities. However, they may suffer from core losses at high frequencies.

C. Ferrite-core Inductors

Ferrite-core inductors are similar to iron-core inductors but use ferrite materials, which have high magnetic permeability and low electrical conductivity. This combination allows for efficient energy storage and minimal losses, making them suitable for a wide range of applications, including power supplies and RF circuits.

D. Toroidal Inductors

Toroidal inductors are wound in a doughnut shape, which helps to confine the magnetic field and reduce electromagnetic interference. They are often used in power supplies and audio equipment due to their compact size and efficiency.

E. Specialty Inductors

Specialty inductors, such as variable inductors and coupled inductors, are designed for specific applications. Variable inductors allow for adjustable inductance, making them useful in tuning circuits, while coupled inductors are used in transformers and other applications requiring magnetic coupling between coils.

III. Key Applications of Inductors

Inductors find applications across various industries, each leveraging their unique properties to enhance performance and efficiency.

A. Power Electronics

Inductors are fundamental components in power electronics, where they are used in:

1. **DC-DC Converters**: Inductors help regulate voltage levels and improve efficiency in converting DC power from one voltage level to another.

2. **Power Supplies**: They are essential in switching power supplies, where they store energy and smooth out voltage fluctuations.

3. **Energy Storage Systems**: Inductors play a critical role in energy storage systems, such as those used in renewable energy applications, by managing energy flow and improving system efficiency.

B. Telecommunications

In telecommunications, inductors are used for:

1. **Signal Filtering**: They help filter out unwanted frequencies, ensuring that only the desired signals are transmitted.

2. **RF Applications**: Inductors are crucial in radio frequency circuits, where they help tune and match impedance for optimal signal transmission.

3. **Antenna Matching**: They are used to match the impedance of antennas to the transmission line, maximizing power transfer and minimizing signal loss.

C. Consumer Electronics

Inductors are prevalent in consumer electronics, including:

1. **Audio Equipment**: They are used in audio amplifiers and speakers to filter signals and improve sound quality.

2. **Home Appliances**: Inductors are found in various appliances, such as refrigerators and washing machines, where they help manage power and improve efficiency.

3. **Mobile Devices**: In smartphones and tablets, inductors are used in power management circuits to optimize battery life and performance.

D. Automotive Industry

The automotive industry increasingly relies on inductors for:

1. **Electric Vehicles (EVs)**: Inductors are essential in EV powertrains, where they manage energy flow and improve efficiency.

2. **Advanced Driver-Assistance Systems (ADAS)**: They are used in sensors and control systems to enhance vehicle safety and performance.

3. **Infotainment Systems**: Inductors help manage power and signal integrity in modern vehicle entertainment systems.

E. Industrial Applications

In industrial settings, inductors are used in:

1. **Motor Drives**: They are critical in controlling motor speed and torque in various applications, from manufacturing to robotics.

2. **Automation Systems**: Inductors help manage power and signals in automated systems, improving efficiency and reliability.

3. **Robotics**: They are used in robotic control systems to ensure precise movement and operation.

F. Medical Devices

Inductors play a vital role in medical devices, including:

1. **Imaging Equipment**: They are used in MRI and CT scanners to manage power and improve image quality.

2. **Monitoring Devices**: Inductors help filter signals in patient monitoring systems, ensuring accurate readings.

3. **Therapeutic Devices**: They are used in devices such as defibrillators and other therapeutic equipment to manage energy delivery.

IV. Trends Influencing Inductor Manufacturing

Several trends are shaping the future of inductor manufacturing, driving innovation and adaptation in the industry.

A. Miniaturization of Electronic Components

As electronic devices become smaller and more compact, the demand for miniaturized inductors is increasing. Manufacturers are focusing on developing smaller, more efficient inductors that can fit into tight spaces without compromising performance.

B. Increasing Demand for Energy Efficiency

With a growing emphasis on sustainability and energy conservation, there is a rising demand for inductors that enhance energy efficiency. Manufacturers are innovating to create inductors that minimize losses and improve overall system performance.

C. Growth of Renewable Energy Technologies

The shift towards renewable energy sources, such as solar and wind, is driving demand for inductors in energy storage systems and power conversion applications. This trend is prompting manufacturers to develop inductors that can handle the unique challenges posed by renewable energy technologies.

D. Advancements in Materials Science

Innovations in materials science are leading to the development of new core materials and winding techniques that enhance inductor performance. These advancements are enabling manufacturers to create inductors with improved efficiency, reduced size, and better thermal management.

E. The Rise of Electric and Hybrid Vehicles

The automotive industry's transition to electric and hybrid vehicles is creating new opportunities for inductor manufacturers. Inductors are essential in managing power in these vehicles, and manufacturers are focusing on developing high-performance inductors that can meet the demands of modern automotive applications.

V. Challenges Faced by Inductor Factories

Despite the promising outlook for inductor manufacturing, several challenges must be addressed.

A. Supply Chain Disruptions

Global supply chain disruptions, exacerbated by events such as the COVID-19 pandemic, have impacted the availability of raw materials and components. Inductor factories must navigate these challenges to maintain production and meet customer demands.

B. Competition from Alternative Technologies

As technology evolves, alternative solutions, such as capacitors and digital signal processing, may compete with inductors in certain applications. Manufacturers must innovate to ensure that inductors remain relevant and competitive.

C. Environmental Regulations

Increasingly stringent environmental regulations are prompting manufacturers to adopt sustainable practices and materials. Inductor factories must invest in eco-friendly processes to comply with regulations and meet consumer expectations.

D. Cost Pressures and Pricing Strategies

Rising raw material costs and competition in the market are putting pressure on pricing strategies. Inductor manufacturers must find ways to optimize production costs while maintaining quality and performance.

VI. Future Directions for Inductor Factories

Looking ahead, inductor factories are poised to explore several future directions to remain competitive and meet evolving market demands.

A. Innovations in Design and Manufacturing Processes

Investing in advanced manufacturing techniques, such as automation and additive manufacturing, can enhance production efficiency and reduce costs. Innovations in design, such as computer-aided design (CAD) and simulation tools, can lead to the development of more efficient inductors.

B. Development of New Materials

Research into new core materials and winding techniques can lead to the creation of inductors with improved performance characteristics. Manufacturers should focus on developing materials that enhance efficiency, reduce size, and improve thermal management.

C. Expansion into Emerging Markets

As global demand for electronic components continues to grow, inductor factories should consider expanding into emerging markets. This expansion can provide new opportunities for growth and diversification.

D. Collaboration with Other Sectors

Collaborating with industries such as automotive, renewable energy, and telecommunications can lead to innovative solutions and new applications for inductors. By working together, manufacturers can leverage expertise and resources to drive advancements in technology.

VII. Conclusion

Inductors are integral components in a wide range of electronic applications, from power electronics to medical devices. As the electronics industry continues to evolve, inductor factories play a crucial role in providing the necessary components that enable technological advancements. The future of inductor manufacturing is shaped by trends such as miniaturization, energy efficiency, and the growth of renewable energy technologies. While challenges such as supply chain disruptions and competition from alternative technologies persist, the potential for innovation and collaboration offers a promising outlook for the industry. As we move forward, the importance of inductors and their applications will only continue to grow, solidifying their place in the ever-evolving landscape of electronics.