How Big is the Market Size of Capacitor Inductors?

I. Introduction

A. Definition of Capacitor Inductors

Capacitor inductors are essential components in electronic circuits, serving as passive elements that store and release electrical energy. Capacitors store energy in an electric field, while inductors store energy in a magnetic field. Together, they play a crucial role in filtering, timing, and energy storage applications across various electronic devices.

B. Importance of Capacitor Inductors in Electronics

The significance of capacitor inductors cannot be overstated. They are integral to the functioning of a wide range of electronic devices, from simple household appliances to complex industrial machinery. Their ability to manage electrical energy efficiently makes them vital in ensuring the reliability and performance of electronic systems.

C. Purpose of the Article

This article aims to explore the market size and trends of capacitor inductors, providing insights into their historical context, current landscape, growth projections, key drivers, challenges, and emerging trends.

II. Overview of the Capacitor Inductor Market

A. Historical Context

1. Evolution of Capacitor Inductors

The development of capacitor inductors dates back to the early days of electrical engineering. Capacitors were first used in the 18th century, while inductors gained prominence in the 19th century with the advent of electromagnetism. Over the decades, advancements in materials and manufacturing processes have led to the creation of more efficient and compact capacitor inductors.

2. Key Milestones in the Industry

Significant milestones in the industry include the introduction of ceramic capacitors in the mid-20th century, which revolutionized the market with their small size and high capacitance. The rise of surface-mount technology (SMT) in the 1980s further propelled the demand for miniaturized capacitor inductors, making them indispensable in modern electronics.

B. Current Market Landscape

1. Major Players in the Market

The capacitor inductor market is characterized by the presence of several key players, including companies like Murata Manufacturing Co., Ltd., Vishay Intertechnology, Inc., and TDK Corporation. These companies dominate the market through continuous innovation and strategic partnerships.

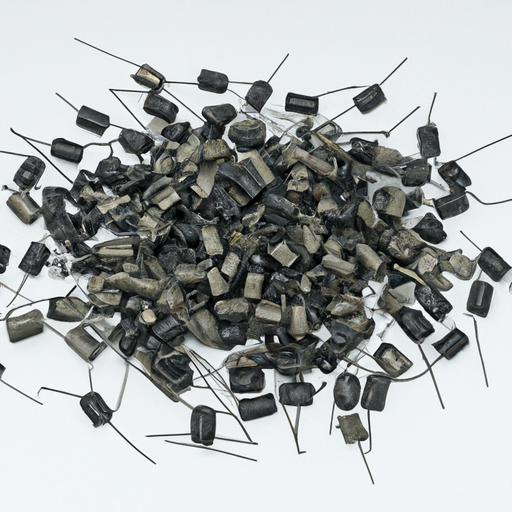

2. Types of Capacitor Inductors

The market comprises various types of capacitor inductors, including:

Film Capacitors: Known for their stability and reliability, film capacitors are widely used in applications requiring high precision.

Ceramic Capacitors: These are popular due to their small size and high capacitance, making them suitable for consumer electronics.

Inductors: Inductors come in various forms, including air-core, iron-core, and ferrite-core, each serving different applications.

Others: This category includes tantalum capacitors, aluminum electrolytic capacitors, and specialty inductors.

III. Market Size and Growth Projections

A. Global Market Size

1. Current Valuation

As of 2023, the global capacitor inductor market is valued at approximately $XX billion, reflecting a robust demand driven by the increasing adoption of electronic devices across various sectors.

2. Historical Growth Rates

The market has experienced steady growth over the past decade, with a compound annual growth rate (CAGR) of around XX%. This growth can be attributed to the rising demand for consumer electronics and advancements in technology.

B. Regional Market Analysis

1. North America

North America holds a significant share of the capacitor inductor market, driven by the presence of major electronics manufacturers and a strong focus on research and development.

2. Europe

Europe is witnessing growth in the capacitor inductor market, fueled by the increasing demand for electric vehicles and renewable energy solutions.

3. Asia-Pacific

The Asia-Pacific region is the fastest-growing market, primarily due to the booming electronics industry in countries like China, Japan, and South Korea.

4. Latin America

Latin America is gradually emerging as a market for capacitor inductors, with increasing investments in infrastructure and technology.

5. Middle East and Africa

The Middle East and Africa are expected to see moderate growth, driven by the expansion of telecommunications and energy sectors.

C. Future Growth Projections

1. Forecast for the Next 5-10 Years

The capacitor inductor market is projected to grow at a CAGR of XX% over the next five to ten years, reaching a valuation of $XX billion by 2030.

2. Factors Influencing Growth

Key factors influencing this growth include technological advancements, increasing demand for energy-efficient solutions, and the proliferation of smart technologies.

IV. Key Drivers of Market Growth

A. Technological Advancements

1. Innovations in Capacitor and Inductor Design

Continuous innovations in capacitor and inductor design are enhancing their performance and efficiency, driving market growth.

2. Miniaturization and Efficiency Improvements

The trend towards miniaturization in electronics is pushing manufacturers to develop smaller and more efficient capacitor inductors.

B. Increasing Demand in Various Industries

1. Consumer Electronics

The consumer electronics sector is a major driver of demand for capacitor inductors, with products like smartphones, laptops, and home appliances requiring reliable energy management.

2. Automotive

The automotive industry is increasingly adopting capacitor inductors for electric vehicles and advanced driver-assistance systems (ADAS).

3. Telecommunications

The rise of 5G technology is creating new opportunities for capacitor inductors in telecommunications infrastructure.

4. Renewable Energy

The shift towards renewable energy sources is driving demand for capacitor inductors in solar inverters and wind turbines.

C. Government Regulations and Standards

1. Environmental Regulations

Government regulations promoting energy efficiency and sustainability are encouraging manufacturers to develop eco-friendly capacitor inductors.

2. Safety Standards

Compliance with safety standards is essential for manufacturers, driving innovation and quality improvements in capacitor inductors.

V. Challenges Facing the Market

A. Supply Chain Issues

1. Raw Material Shortages

The capacitor inductor market faces challenges related to raw material shortages, impacting production and pricing.

2. Manufacturing Constraints

Manufacturing constraints, including labor shortages and production delays, can hinder market growth.

B. Competition and Market Saturation

Intense competition and market saturation pose challenges for manufacturers, requiring them to differentiate their products and innovate continuously.

C. Technological Obsolescence

Rapid technological advancements can lead to obsolescence, necessitating ongoing investment in research and development.

VI. Market Trends

A. Shift Towards Sustainable Solutions

1. Eco-friendly Materials

There is a growing trend towards the use of eco-friendly materials in the production of capacitor inductors, aligning with global sustainability goals.

2. Recycling and Reusability

Manufacturers are increasingly focusing on recycling and reusability to minimize waste and environmental impact.

B. Rise of Smart Technologies

1. Internet of Things (IoT)

The proliferation of IoT devices is driving demand for advanced capacitor inductors that can support smart applications.

2. Smart Grids

The development of smart grids is creating new opportunities for capacitor inductors in energy management and distribution.

C. Customization and Specialization

1. Tailored Solutions for Specific Applications

Manufacturers are increasingly offering customized solutions to meet the specific needs of various industries, enhancing their competitive edge.

VII. Conclusion

A. Summary of Key Findings

The capacitor inductor market is poised for significant growth, driven by technological advancements, increasing demand across various industries, and a shift towards sustainable solutions.

B. Future Outlook for the Capacitor Inductor Market

With a projected CAGR of XX% over the next decade, the market is expected to reach a valuation of $XX billion by 2030, presenting ample opportunities for manufacturers and investors.

C. Final Thoughts on the Importance of Understanding Market Dynamics

Understanding the dynamics of the capacitor inductor market is crucial for stakeholders to navigate challenges and capitalize on emerging opportunities. As technology continues to evolve, staying informed about market trends and drivers will be essential for success in this vital sector.

VIII. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Power Electronics

B. Industry Reports

- Market Research Future Reports

- Grand View Research Publications

C. Market Research Publications

- Research and Markets

- Mordor Intelligence

D. Relevant Websites and Articles

- Electronics Weekly

- EDN Network

---

This blog post provides a comprehensive overview of the capacitor inductor market, covering its historical context, current landscape, growth projections, key drivers, challenges, and emerging trends. Each section is designed to offer valuable insights into the market dynamics, making it a useful resource for industry stakeholders.