Understanding Wire-Wound Inductors

I. Introduction

Inductors are fundamental components in electrical circuits, playing a crucial role in energy storage, filtering, and signal processing. Among the various types of inductors, wire-wound inductors are particularly noteworthy due to their unique construction and performance characteristics. This article aims to provide a comprehensive understanding of wire-wound inductors, exploring their design, working principles, advantages, applications, and limitations.

II. Basic Concepts of Inductance

A. Definition of Inductance

Inductance is the property of an electrical component that allows it to store energy in a magnetic field when an electric current flows through it. The unit of inductance is the henry (H), named after the American scientist Joseph Henry. Inductance is a critical parameter in the design and function of inductors, influencing how they behave in various electrical circuits.

B. The Role of Inductors in Electrical Circuits

Inductors serve several essential functions in electrical circuits:

1. **Energy Storage**: Inductors can store energy in the form of a magnetic field, which can be released back into the circuit when needed.

2. **Filtering and Smoothing**: Inductors are commonly used in power supply circuits to filter out unwanted noise and smooth voltage fluctuations.

3. **Signal Processing**: In communication systems, inductors help in tuning circuits and signal modulation.

C. Types of Inductors

Inductors come in various types, each suited for specific applications:

1. **Air-Core Inductors**: These inductors do not use a magnetic core, relying solely on the air surrounding the coil for inductance.

2. **Ferrite-Core Inductors**: These inductors use ferrite materials to enhance inductance and reduce losses.

3. **Wire-Wound Inductors**: These inductors are constructed by winding wire around a core, providing high inductance values in a compact form.

III. What is a Wire-Wound Inductor?

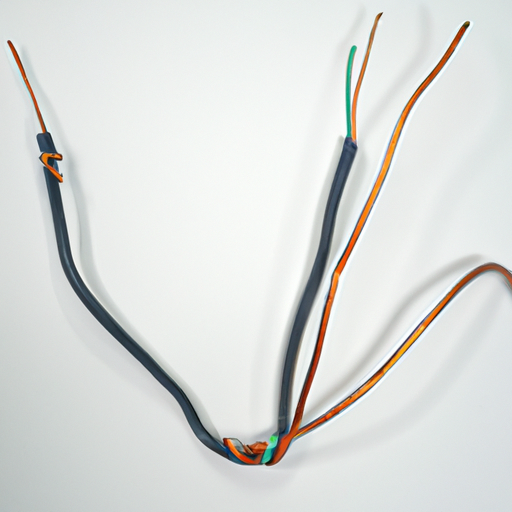

A. Construction and Materials

Wire-wound inductors are made by winding conductive wire, typically copper or aluminum, around a core material. The choice of wire and core material significantly affects the inductor's performance.

1. **Wire Types**: Copper is the most common choice due to its excellent conductivity, while aluminum is lighter and less expensive but has higher resistance.

2. **Core Materials**: The core can be made of air, ferrite, or other materials, influencing the inductor's inductance and efficiency.

B. Design Variations

Wire-wound inductors come in various designs to meet different application needs:

1. **Single-Layer vs. Multi-Layer Windings**: Single-layer windings are simpler and cheaper, while multi-layer windings can achieve higher inductance in a smaller space.

2. **Toroidal vs. Cylindrical Shapes**: Toroidal inductors have a donut shape, which minimizes electromagnetic interference, while cylindrical inductors are easier to manufacture.

C. Key Specifications

When selecting a wire-wound inductor, several key specifications must be considered:

1. **Inductance Value**: Measured in henries, this indicates the inductor's ability to store energy.

2. **Current Rating**: This specifies the maximum current the inductor can handle without overheating.

3. **DC Resistance**: Lower resistance is preferable to minimize energy loss.

4. **Quality Factor (Q)**: A higher Q indicates better performance, particularly at high frequencies.

IV. Working Principle of Wire-Wound Inductors

A. Electromagnetic Induction

The working principle of wire-wound inductors is based on electromagnetic induction, where a changing current through the wire creates a magnetic field around it. This magnetic field can induce a voltage in the wire itself or in nearby conductors.

B. How Current Flow Creates a Magnetic Field

When current flows through the wire, it generates a magnetic field proportional to the amount of current and the number of turns in the coil. The direction of the magnetic field follows the right-hand rule, where the thumb points in the direction of current flow, and the curled fingers indicate the direction of the magnetic field.

C. The Relationship Between Inductance and Coil Parameters

The inductance of a wire-wound inductor is influenced by several factors, including the number of turns in the coil, the core material, and the coil's geometry. The formula for inductance (L) is given by:

\[ L = \frac{N^2 \cdot \mu \cdot A}{l} \]

Where:

- \( N \) = number of turns

- \( \mu \) = permeability of the core material

- \( A \) = cross-sectional area of the coil

- \( l \) = length of the coil

V. Advantages of Wire-Wound Inductors

Wire-wound inductors offer several advantages that make them suitable for various applications:

A. High Inductance Values in a Compact Size

Due to their construction, wire-wound inductors can achieve high inductance values in a relatively small footprint, making them ideal for space-constrained applications.

B. Better Performance at High Frequencies

Wire-wound inductors typically exhibit better performance at high frequencies compared to other types, making them suitable for RF applications.

C. Improved Thermal Stability

These inductors can handle higher temperatures without significant performance degradation, which is crucial in demanding environments.

D. Customizability for Specific Applications

Wire-wound inductors can be tailored to meet specific requirements, such as inductance value, current rating, and physical dimensions, allowing for greater flexibility in design.

VI. Applications of Wire-Wound Inductors

Wire-wound inductors are widely used across various industries and applications:

A. Power Supply Circuits

In power supply circuits, wire-wound inductors help filter out noise and stabilize voltage levels, ensuring reliable operation.

B. RF Applications

These inductors are essential in radio frequency applications, where they are used in tuning circuits and signal processing.

C. Audio Equipment

Wire-wound inductors are commonly found in audio equipment, where they help filter and smooth audio signals for better sound quality.

D. Signal Processing and Filtering

In communication systems, wire-wound inductors play a vital role in signal processing and filtering, ensuring clear and accurate transmission.

E. Automotive Electronics

With the increasing complexity of automotive electronics, wire-wound inductors are used in various applications, including power management and signal processing.

VII. Limitations of Wire-Wound Inductors

Despite their advantages, wire-wound inductors also have some limitations:

A. Size and Weight Considerations

While they can achieve high inductance values in a compact size, wire-wound inductors can still be bulkier and heavier than other types, such as surface-mount inductors.

B. Saturation Effects

At high current levels, wire-wound inductors can experience saturation, where the inductance value decreases significantly, leading to reduced performance.

C. Cost Factors Compared to Other Inductor Types

Wire-wound inductors can be more expensive than other types, such as air-core inductors, due to their complex manufacturing processes.

D. Inductance Variation with Temperature

The inductance value of wire-wound inductors can vary with temperature, which may affect their performance in certain applications.

VIII. Selecting the Right Wire-Wound Inductor

When selecting a wire-wound inductor, several factors should be considered:

A. Factors to Consider

1. **Application Requirements**: Understand the specific needs of your application, including inductance value, current rating, and frequency range.

2. **Inductance and Current Ratings**: Ensure the inductor meets the required specifications for your circuit.

3. **Environmental Conditions**: Consider factors such as temperature, humidity, and potential exposure to contaminants.

B. Common Manufacturers and Product Lines

Several manufacturers specialize in wire-wound inductors, offering a range of products to suit various applications. Researching reputable manufacturers can help you find the right inductor for your needs.

IX. Conclusion

Wire-wound inductors are essential components in electrical engineering, providing high inductance values, excellent performance at high frequencies, and customizability for specific applications. Understanding their construction, working principles, advantages, and limitations is crucial for selecting the right inductor for your projects. As technology continues to evolve, wire-wound inductors will remain a vital part of modern electrical circuits, and further exploration of their capabilities will undoubtedly yield exciting advancements in the field.

X. References

For those interested in delving deeper into the world of wire-wound inductors, consider exploring the following resources:

1. "Inductor Design and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By understanding wire-wound inductors, engineers and hobbyists alike can harness their potential to create efficient and effective electrical circuits.