What are the Prices of Hot Spot Capacitor Charging and Discharging Models?

I. Introduction

In the realm of electrical engineering, capacitors play a pivotal role in various applications, from energy storage to signal processing. Among these, hot spot capacitors have gained attention due to their unique characteristics and performance in high-demand environments. Understanding the pricing of hot spot capacitor charging and discharging models is crucial for engineers and businesses alike, as it directly impacts project budgets and design choices. This article will delve into the intricacies of hot spot capacitors, their charging and discharging models, and the factors influencing their prices.

II. Understanding Hot Spot Capacitors

A. Explanation of Capacitors in Electrical Systems

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field develops across the plates, allowing the capacitor to store energy. Capacitors are widely used in various applications, including power supply smoothing, energy storage systems, and timing circuits.

1. Functionality and Applications

Capacitors serve multiple functions in electrical systems, such as filtering, coupling, decoupling, and energy storage. They are essential in power electronics, automotive systems, and renewable energy applications, where they help manage energy flow and improve system efficiency.

2. Types of Capacitors

There are several types of capacitors, including ceramic, electrolytic, tantalum, and film capacitors. Each type has its unique characteristics, making them suitable for specific applications. Hot spot capacitors, a specialized category, are designed to operate efficiently under high-performance conditions.

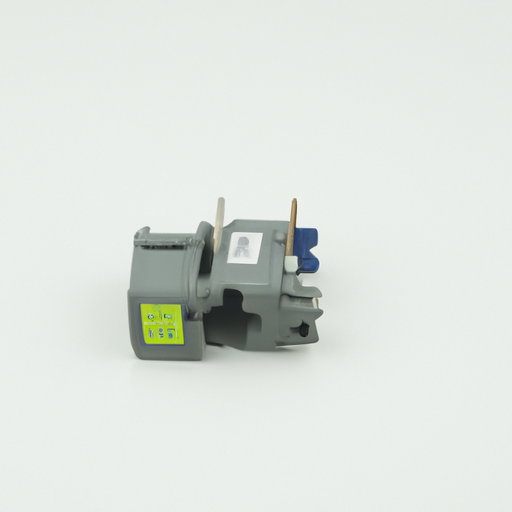

B. What are Hot Spot Capacitors?

1. Definition and Characteristics

Hot spot capacitors are designed to handle high temperatures and rapid charging and discharging cycles. They are characterized by their ability to maintain performance under extreme conditions, making them ideal for applications such as electric vehicles, renewable energy systems, and high-frequency circuits.

2. Importance in High-Performance Applications

In high-performance applications, the reliability and efficiency of capacitors are paramount. Hot spot capacitors provide enhanced thermal management and reduced losses, ensuring optimal performance in demanding environments.

III. Charging and Discharging Models

A. Overview of Charging Models

1. Basic Principles of Charging

Charging a capacitor involves applying a voltage across its plates, allowing it to accumulate electrical energy. The charging process is governed by the capacitor's capacitance and the resistance in the circuit, which determines the time constant of the charging process.

2. Factors Affecting Charging Time and Efficiency

Several factors influence the charging time and efficiency of hot spot capacitors, including the applied voltage, the resistance of the circuit, and the capacitor's capacitance. Additionally, temperature and the dielectric material used can impact performance.

B. Overview of Discharging Models

1. Basic Principles of Discharging

Discharging a capacitor involves releasing the stored energy back into the circuit. The discharge process is also influenced by the circuit's resistance and the capacitor's capacitance, similar to the charging process.

2. Factors Affecting Discharge Time and Efficiency

The discharge time and efficiency are affected by the load connected to the capacitor, the initial charge voltage, and the characteristics of the capacitor itself. Understanding these factors is crucial for designing efficient energy systems.

C. Importance of Accurate Models in Design and Simulation

Accurate charging and discharging models are essential for engineers to simulate and design electrical systems effectively. These models help predict performance, optimize designs, and ensure reliability in real-world applications.

IV. Pricing Factors for Hot Spot Capacitor Models

A. Components of Pricing

1. Material Costs

The materials used in manufacturing hot spot capacitors significantly impact their pricing. High-quality dielectrics and conductive materials are essential for performance but can increase production costs.

2. Manufacturing Processes

The complexity of the manufacturing process also affects pricing. Advanced techniques, such as thin-film deposition and precision assembly, can lead to higher costs but result in superior performance.

3. Research and Development

Investment in research and development is crucial for innovation in capacitor technology. Manufacturers that prioritize R&D may charge higher prices for their products, reflecting the advanced features and reliability they offer.

B. Market Demand and Supply Dynamics

The demand for hot spot capacitors is influenced by trends in industries such as automotive, renewable energy, and consumer electronics. Fluctuations in demand can lead to price variations, as manufacturers adjust their production to meet market needs.

C. Technological Advancements and Their Impact on Pricing

As technology advances, new materials and manufacturing techniques emerge, potentially lowering production costs and improving performance. However, initial investments in new technologies can lead to higher prices until economies of scale are achieved.

D. Geographic Variations in Pricing

Pricing for hot spot capacitors can vary by region due to factors such as labor costs, material availability, and local market conditions. Understanding these geographic variations is essential for businesses sourcing components globally.

V. Price Ranges for Hot Spot Capacitor Models

A. Entry-Level Models

1. Features and Specifications

Entry-level hot spot capacitors typically offer basic performance characteristics suitable for less demanding applications. They may have lower capacitance values and simpler designs.

2. Typical Price Range

The price for entry-level models generally ranges from $5 to $20, depending on the specifications and manufacturer.

B. Mid-Range Models

1. Features and Specifications

Mid-range hot spot capacitors provide enhanced performance, including higher capacitance values and improved thermal management. They are suitable for a broader range of applications.

2. Typical Price Range

Mid-range models typically cost between $20 and $100, reflecting their advanced features and reliability.

C. High-End Models

1. Features and Specifications

High-end hot spot capacitors are designed for the most demanding applications, offering superior performance, high capacitance values, and advanced thermal management capabilities.

2. Typical Price Range

Prices for high-end models can range from $100 to $500 or more, depending on the specific features and manufacturer.

D. Custom Models and Their Pricing

Custom hot spot capacitors are tailored to meet specific application requirements. Pricing for these models can vary widely based on design complexity and performance specifications, often starting at $500 and going up significantly.

VI. Case Studies

A. Comparison of Prices from Different Manufacturers

A comparative analysis of prices from various manufacturers reveals significant differences based on brand reputation, technology, and performance. For instance, a well-established manufacturer may charge a premium for their hot spot capacitors due to their proven reliability.

B. Analysis of Pricing Trends Over Time

Over the past decade, the prices of hot spot capacitors have generally trended downward due to advancements in manufacturing processes and materials. However, fluctuations in raw material costs and market demand can lead to temporary price increases.

C. Impact of Industry Standards on Pricing

Industry standards play a crucial role in determining pricing. Manufacturers that comply with stringent standards may incur higher production costs, which can be reflected in the final price of their products.

VII. Conclusion

In conclusion, understanding the prices of hot spot capacitor charging and discharging models is essential for engineers and businesses involved in electrical engineering. The pricing is influenced by various factors, including material costs, manufacturing processes, and market dynamics. By carefully considering these factors, professionals can make informed decisions that align with their budget and performance requirements. As technology continues to evolve, we can expect further advancements in hot spot capacitor pricing and performance, paving the way for more efficient and reliable electrical systems.

VIII. References

- Academic Journals on Electrical Engineering

- Industry Reports on Capacitor Technology

- Manufacturer Websites and Product Catalogs

This comprehensive overview provides insights into the pricing of hot spot capacitor charging and discharging models, equipping readers with the knowledge needed to navigate this critical aspect of electrical engineering.