The Latest Reactive Power Compensation Capacitor Specifications

I. Introduction

In the realm of electrical engineering, reactive power compensation plays a crucial role in maintaining the efficiency and stability of power systems. Reactive power, which is essential for the functioning of inductive loads such as motors and transformers, can lead to inefficiencies if not properly managed. Capacitors are vital components in this process, providing reactive power support and improving overall power quality. This article aims to explore the latest specifications for reactive power compensation capacitors, highlighting their importance, functionality, and applications in modern power systems.

II. Understanding Reactive Power

A. Definition of Reactive Power

Reactive power is the power that oscillates between the source and the load in an AC system, primarily due to inductive and capacitive elements. Unlike active power, which performs useful work, reactive power is necessary for establishing electric and magnetic fields in devices like motors and transformers.

B. Role of Reactive Power in Electrical Systems

In electrical systems, reactive power is essential for voltage regulation and maintaining the stability of the grid. It helps in the proper functioning of equipment and ensures that the voltage levels remain within acceptable limits. Without adequate reactive power, voltage drops can occur, leading to equipment malfunction and increased losses.

C. Consequences of Poor Reactive Power Management

Inefficient reactive power management can result in several issues, including increased energy costs, reduced system capacity, and potential equipment damage. Utilities may impose penalties on consumers with poor power factor ratings, making it imperative for industries to invest in reactive power compensation solutions.

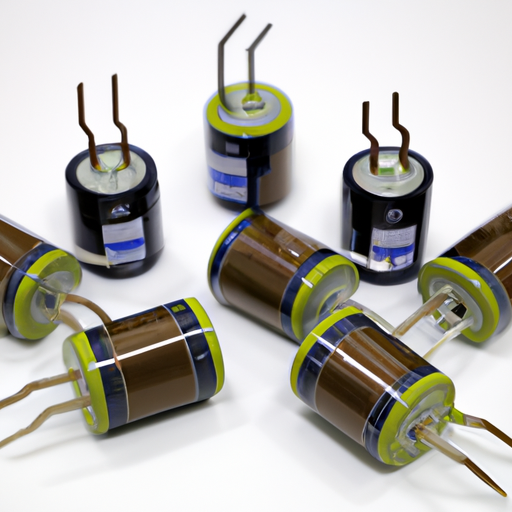

III. Overview of Capacitors in Reactive Power Compensation

A. Types of Capacitors Used

1. **Fixed Capacitors**: These capacitors provide a constant reactive power output and are typically used in applications where the load is stable.

2. **Automatic Capacitors**: Equipped with control systems, these capacitors can adjust their output based on real-time load conditions, making them suitable for dynamic environments.

3. **Synchronous Condensers**: These are rotating machines that can provide both reactive power and voltage support, often used in large industrial applications.

B. Basic Functionality of Capacitors in Power Systems

Capacitors store and release electrical energy, providing reactive power support when needed. They help in correcting power factor, reducing losses, and improving voltage stability in the system.

C. Benefits of Using Capacitors for Reactive Power Compensation

The use of capacitors for reactive power compensation offers several benefits, including improved energy efficiency, reduced electricity costs, enhanced voltage stability, and increased system capacity. By optimizing the power factor, industries can also avoid penalties from utilities.

IV. Latest Specifications for Reactive Power Compensation Capacitors

A. Voltage Ratings

1. **Standard Voltage Levels**: Capacitors are available in various voltage ratings, typically ranging from 230V to 690V for low-voltage applications.

2. **High Voltage Capacitors**: For high-voltage applications, capacitors can be rated up to 36kV or more, catering to the needs of industrial and utility-scale installations.

B. Capacitance Values

1. **Range of Capacitance Values**: Capacitors come in a wide range of capacitance values, from microfarads (µF) for small applications to several hundred microfarads for larger systems.

2. **Selection Criteria Based on Application**: The selection of capacitance values depends on the specific application, load characteristics, and desired power factor correction level.

C. Power Factor Improvement

1. **Target Power Factor Levels**: Industries typically aim for a power factor of 0.95 or higher to avoid penalties and improve efficiency.

2. **Measurement and Monitoring Techniques**: Advanced monitoring systems can provide real-time data on power factor levels, enabling timely adjustments to capacitor banks.

D. Harmonic Distortion Considerations

1. **Impact of Harmonics on Capacitor Performance**: Harmonic distortion can adversely affect capacitor performance, leading to overheating and premature failure.

2. **Specifications for Harmonic Filtering**: Capacitors designed for reactive power compensation should include harmonic filtering capabilities to mitigate the effects of harmonics in the system.

E. Temperature and Environmental Ratings

1. **Operating Temperature Ranges**: Capacitors are rated for specific temperature ranges, typically from -40°C to +50°C, ensuring reliable operation in various environments.

2. **Environmental Protection Standards (IP Ratings)**: Capacitors may also have IP ratings indicating their resistance to dust and moisture, which is crucial for outdoor installations.

V. Standards and Regulations

A. International Standards (IEC, IEEE)

Reactive power compensation capacitors must comply with international standards such as those set by the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). These standards ensure safety, reliability, and performance consistency.

B. National Standards and Compliance

In addition to international standards, various countries have their own regulations governing capacitor specifications. Compliance with these standards is essential for manufacturers and users alike.

C. Importance of Adhering to Specifications

Adhering to established specifications is critical for ensuring the longevity and reliability of capacitor systems. Non-compliance can lead to operational failures, safety hazards, and increased maintenance costs.

VI. Applications of Reactive Power Compensation Capacitors

A. Industrial Applications

1. **Manufacturing Facilities**: Capacitors are widely used in manufacturing plants to improve power factor and reduce energy costs associated with inductive loads.

2. **Data Centers**: With the increasing demand for energy efficiency, data centers utilize capacitors to manage reactive power and maintain optimal operating conditions.

B. Commercial Applications

1. **Retail Spaces**: Retail establishments benefit from reactive power compensation by reducing electricity bills and improving overall energy efficiency.

2. **Office Buildings**: Capacitors help office buildings maintain voltage stability and reduce energy costs, contributing to a more sustainable operation.

C. Renewable Energy Integration

1. **Wind Farms**: Capacitors play a vital role in wind energy systems, providing reactive power support to maintain grid stability.

2. **Solar Power Plants**: In solar installations, capacitors help manage reactive power and improve the overall efficiency of the system.

VII. Case Studies

A. Successful Implementation of Capacitor Systems

Numerous industries have successfully implemented capacitor systems to enhance their power factor and reduce energy costs. For instance, a manufacturing facility that installed automatic capacitor banks reported a 20% reduction in electricity costs.

B. Lessons Learned from Failures

Conversely, some installations have failed due to improper sizing or lack of harmonic filtering. These cases highlight the importance of thorough analysis and adherence to specifications during the design phase.

C. Comparative Analysis of Different Capacitor Technologies

A comparative analysis of fixed, automatic, and synchronous capacitor technologies reveals that while fixed capacitors are cost-effective, automatic systems offer greater flexibility and efficiency in dynamic environments.

VIII. Future Trends in Reactive Power Compensation

A. Technological Advancements

1. **Smart Capacitors**: The integration of smart technology in capacitors allows for real-time monitoring and automated adjustments, enhancing their effectiveness in reactive power compensation.

2. **Integration with IoT**: The Internet of Things (IoT) is set to revolutionize the way reactive power compensation systems are managed, providing data-driven insights for optimization.

B. Evolving Industry Needs

1. **Increased Demand for Energy Efficiency**: As industries strive for sustainability, the demand for efficient reactive power compensation solutions will continue to grow.

2. **Impact of Electric Vehicles on Power Systems**: The rise of electric vehicles presents new challenges for power systems, necessitating advanced reactive power management strategies to accommodate increased load demands.

IX. Conclusion

In conclusion, reactive power compensation capacitors are essential components in modern power systems, playing a critical role in enhancing energy efficiency and maintaining grid stability. Staying updated with the latest specifications and technologies is vital for industry professionals to ensure optimal performance and compliance. As the demand for energy-efficient solutions continues to rise, the importance of reactive power compensation will only grow, making it imperative for stakeholders to invest in the right technologies and practices.

X. References

1. International Electrotechnical Commission (IEC) Standards

2. Institute of Electrical and Electronics Engineers (IEEE) Publications

3. Academic Journals on Power Systems and Energy Efficiency

4. Industry Reports on Reactive Power Compensation Technologies

5. Standards Documentation for Capacitor Specifications

This comprehensive overview of the latest specifications for reactive power compensation capacitors provides valuable insights for industry professionals, ensuring they are well-equipped to navigate the evolving landscape of power systems.