What is the Mainstream Production Process of Programmable Resistors?

I. Introduction

A. Definition of Programmable Resistors

Programmable resistors are electronic components that allow for the adjustment of resistance values through digital or analog control. Unlike traditional resistors, which have fixed resistance values, programmable resistors can be modified to meet specific circuit requirements. This flexibility makes them invaluable in various applications, from consumer electronics to industrial automation.

B. Importance in Modern Electronics

In today's fast-paced technological landscape, the ability to adapt and customize electronic components is crucial. Programmable resistors play a significant role in enhancing the functionality and efficiency of electronic devices. They enable designers to create more compact and versatile circuits, reduce the number of components needed, and improve overall performance. As a result, programmable resistors are increasingly integrated into modern electronic systems.

C. Overview of the Production Process

The production of programmable resistors involves several stages, including material selection, design and engineering, manufacturing, testing, calibration, and programming. Each phase is critical to ensuring that the final product meets the required specifications and performance standards. This blog post will delve into each of these stages, providing a comprehensive overview of the mainstream production process of programmable resistors.

II. Types of Programmable Resistors

A. Digital Programmable Resistors

Digital programmable resistors are controlled through digital signals, typically using a microcontroller or digital signal processor. They offer precise resistance values and can be easily integrated into digital circuits. These resistors are commonly used in applications where accurate resistance adjustments are necessary, such as in digital potentiometers.

B. Analog Programmable Resistors

Analog programmable resistors, on the other hand, allow for continuous adjustment of resistance values. They are often used in applications requiring variable resistance, such as audio equipment and signal processing. Analog programmable resistors can be controlled through voltage or current signals, providing a more fluid adjustment compared to their digital counterparts.

C. Comparison of Different Types

While both digital and analog programmable resistors serve similar purposes, their applications and control methods differ significantly. Digital programmable resistors are ideal for applications requiring precise control and repeatability, while analog programmable resistors are better suited for applications needing smooth and continuous adjustments. Understanding these differences is essential for selecting the right type of programmable resistor for a specific application.

III. Materials Used in Production

A. Conductive Materials

The choice of materials is critical in the production of programmable resistors.

1. Carbon-based materials

Carbon-based materials, such as carbon film and carbon composite, are commonly used due to their excellent conductivity and stability. These materials can be easily manipulated to achieve the desired resistance values, making them a popular choice for both digital and analog programmable resistors.

2. Metal oxide materials

Metal oxide materials, such as tin oxide and indium tin oxide, are also used in the production of programmable resistors. These materials offer high thermal stability and can withstand harsh environmental conditions, making them suitable for industrial applications.

B. Insulating Materials

Insulating materials are essential for preventing unwanted current flow and ensuring the reliability of programmable resistors. Common insulating materials include ceramics and polymers, which provide excellent dielectric properties and thermal stability.

C. Substrate Materials

The substrate serves as the foundation for the resistor and plays a crucial role in its performance. Silicon wafers are commonly used as substrates due to their excellent electrical properties and compatibility with semiconductor manufacturing processes.

IV. Design and Engineering Phase

A. Circuit Design Considerations

The design of programmable resistors begins with circuit design considerations. Engineers must determine the required resistance range, tolerance, and power rating based on the intended application. Additionally, the integration of programmable resistors into existing circuits requires careful planning to ensure compatibility and optimal performance.

B. Simulation and Modeling

Once the initial design is complete, engineers use simulation and modeling tools to predict the performance of the programmable resistor. These tools allow for the analysis of various parameters, such as temperature coefficients, noise levels, and response times, helping to identify potential issues before moving to the manufacturing phase.

C. Prototyping

After simulations, prototypes of the programmable resistors are created for testing and validation. Prototyping allows engineers to assess the performance of the resistor in real-world conditions and make necessary adjustments to the design before full-scale production.

V. Manufacturing Process

A. Wafer Fabrication

The manufacturing process of programmable resistors begins with wafer fabrication, which involves several key steps:

1. Photolithography

Photolithography is used to create patterns on the silicon wafer. A photosensitive material, known as photoresist, is applied to the wafer's surface, and ultraviolet light is used to expose specific areas. This process defines the regions where conductive and insulating materials will be deposited.

2. Etching

After photolithography, the wafer undergoes etching to remove unwanted material. This step is crucial for creating the desired resistor structure and ensuring precise resistance values.

3. Doping

Doping involves introducing impurities into the silicon wafer to modify its electrical properties. This process is essential for creating the conductive pathways within the programmable resistor.

B. Thin-Film Deposition

Thin-film deposition techniques are employed to apply conductive and insulating materials to the wafer.

1. Sputtering

Sputtering is a physical vapor deposition method that involves bombarding a target material with ions, causing atoms to be ejected and deposited onto the wafer. This technique is commonly used to create thin conductive films.

2. Chemical Vapor Deposition (CVD)

CVD is another deposition method that involves the chemical reaction of gaseous precursors to form solid materials on the wafer's surface. This technique is often used for depositing insulating layers and metal oxides.

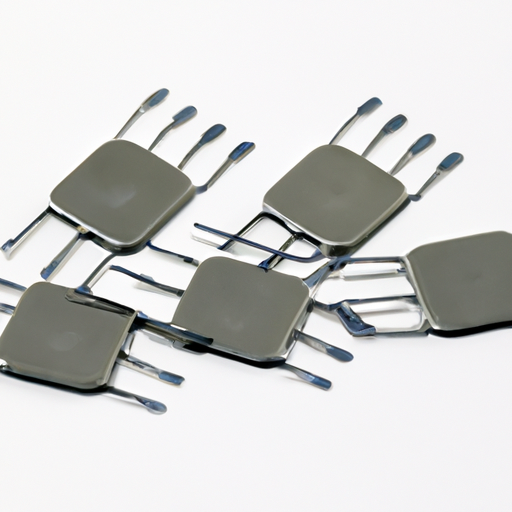

C. Assembly and Packaging

Once the wafer fabrication is complete, the programmable resistors undergo assembly and packaging.

1. Die Attachment

The individual resistor dies are attached to a substrate or package using adhesive materials. This step ensures mechanical stability and electrical connectivity.

2. Wire Bonding

Wire bonding is used to connect the resistor die to external leads. This process involves using fine wires to create electrical connections, allowing the resistor to be integrated into electronic circuits.

3. Encapsulation

Finally, the assembled resistors are encapsulated to protect them from environmental factors such as moisture and dust. Encapsulation materials can include epoxy resins or silicone compounds, providing durability and reliability.

VI. Testing and Quality Control

A. Electrical Testing

Once the programmable resistors are manufactured, they undergo rigorous electrical testing to ensure they meet specified performance criteria. This testing includes measuring resistance values, tolerance, and temperature coefficients.

B. Environmental Testing

Environmental testing assesses the performance of programmable resistors under various conditions, such as temperature fluctuations, humidity, and exposure to chemicals. This testing is crucial for ensuring the reliability of resistors in real-world applications.

C. Reliability Testing

Reliability testing evaluates the long-term performance of programmable resistors. This testing may involve accelerated aging tests, thermal cycling, and mechanical stress tests to identify potential failure modes and ensure the resistors can withstand the rigors of their intended applications.

VII. Calibration and Programming

A. Calibration Techniques

Calibration is essential for ensuring the accuracy of programmable resistors. Various calibration techniques are employed, including using precision reference resistors and automated calibration systems to adjust resistance values to the desired specifications.

B. Programming Methods

Programming methods vary depending on the type of programmable resistor. Digital programmable resistors are typically programmed using digital signals, while analog programmable resistors may be adjusted using voltage or current inputs. Understanding these methods is crucial for integrating programmable resistors into electronic systems.

C. Integration with Control Systems

Programmable resistors are often integrated with control systems, such as microcontrollers or digital signal processors, to enable real-time adjustments. This integration allows for dynamic control of resistance values, enhancing the functionality of electronic devices.

VIII. Applications of Programmable Resistors

A. Consumer Electronics

In consumer electronics, programmable resistors are used in devices such as audio equipment, televisions, and smartphones. They enable features like volume control, tone adjustment, and signal processing, enhancing user experience.

B. Automotive Industry

In the automotive industry, programmable resistors are employed in various applications, including engine control units, sensor calibration, and adaptive lighting systems. Their ability to provide precise resistance adjustments contributes to improved vehicle performance and safety.

C. Industrial Automation

Programmable resistors play a vital role in industrial automation, where they are used in control systems, robotics, and process monitoring. Their flexibility allows for the customization of control parameters, optimizing efficiency and productivity.

D. Medical Devices

In medical devices, programmable resistors are used in diagnostic equipment, monitoring systems, and therapeutic devices. Their reliability and precision are critical for ensuring accurate measurements and effective treatments.

IX. Future Trends in Programmable Resistor Technology

A. Advances in Materials Science

Ongoing research in materials science is expected to lead to the development of new conductive and insulating materials, enhancing the performance and reliability of programmable resistors. These advancements may also enable the creation of smaller and more efficient resistors.

B. Miniaturization and Integration

As electronic devices continue to shrink in size, the demand for miniaturized programmable resistors will increase. Future trends may focus on integrating programmable resistors with other components, such as capacitors and inductors, to create compact multifunctional devices.

C. Smart and Adaptive Systems

The rise of smart and adaptive systems will drive the demand for programmable resistors that can respond to changing conditions in real-time. This trend will likely lead to the development of more sophisticated control algorithms and integration with artificial intelligence technologies.

X. Conclusion

A. Summary of the Production Process

The production process of programmable resistors involves several critical stages, including material selection, design and engineering, manufacturing, testing, calibration, and programming. Each phase is essential for ensuring the final product meets the required specifications and performance standards.

B. Importance of Programmable Resistors in Technology

Programmable resistors are vital components in modern electronics, enabling flexibility, customization, and improved performance in various applications. Their ability to adapt to changing conditions makes them indispensable in today's technology-driven world.

C. Future Outlook and Innovations

As technology continues to evolve, the demand for programmable resistors will only increase. Ongoing advancements in materials science, miniaturization, and smart systems will shape the future of programmable resistor technology, paving the way for innovative applications and enhanced performance in electronic devices. The future looks promising for programmable resistors, and their role in shaping the next generation of electronics will be significant.