What are the Mainstream Models of Chip Inductors?

I. Introduction

A. Definition of Chip Inductors

Chip inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are essential in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. Unlike traditional inductors, chip inductors are compact and designed for surface mounting, making them ideal for modern electronic devices where space is at a premium.

B. Importance of Chip Inductors in Electronics

In the rapidly evolving world of electronics, chip inductors play a crucial role in enhancing performance and efficiency. They are integral to power management systems, radio frequency (RF) applications, and signal filtering, among other uses. As devices become smaller and more complex, the demand for high-performance chip inductors continues to grow, driving innovation in design and manufacturing.

C. Overview of the Article

This article will explore the various types of chip inductors, focusing on mainstream models, their specifications, applications, and the latest trends in technology. By understanding these components, engineers and designers can make informed decisions when selecting inductors for their projects.

II. Understanding Chip Inductors

A. Basic Principles of Inductance

1. Definition of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage in the coil that opposes the change in current. This phenomenon is known as self-induction.

2. Role of Inductors in Circuits

Inductors are used in various applications, including filtering out unwanted signals, storing energy in power supplies, and tuning circuits to specific frequencies. They are essential in applications such as radio transmitters and receivers, where they help select and amplify desired signals.

B. Structure and Components of Chip Inductors

1. Core Materials

Chip inductors can be made from various core materials, including ferrite and air. Ferrite cores are commonly used due to their high magnetic permeability, which enhances inductance. Air core inductors, on the other hand, are less affected by saturation and are suitable for high-frequency applications.

2. Wire Winding Techniques

The winding technique used in chip inductors affects their performance. Traditional wire-wound inductors are made by winding copper wire around a core, while multilayer inductors use thin film technology to create multiple layers of inductance in a compact form.

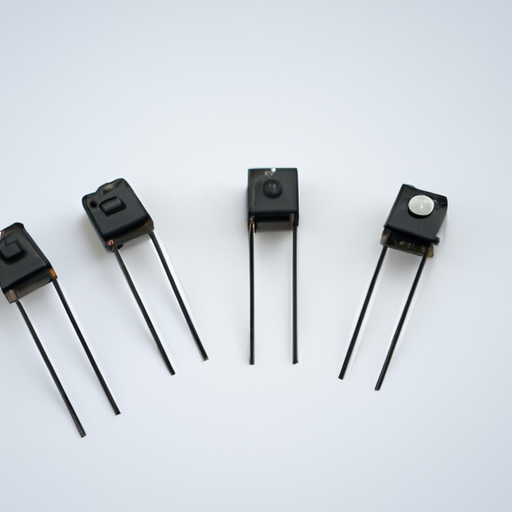

3. Packaging and Form Factors

Chip inductors come in various package sizes and shapes, including rectangular and cylindrical forms. The choice of packaging affects the inductor's performance, thermal characteristics, and ease of integration into circuits.

III. Types of Chip Inductors

A. Fixed Inductors

1. Characteristics and Applications

Fixed inductors have a predetermined inductance value and are widely used in power supply circuits, RF applications, and signal filtering. They are available in various inductance values and current ratings.

2. Common Models and Specifications

Popular models include the Murata LQH series and TDK CL series, which offer a range of inductance values and sizes suitable for different applications.

B. Variable Inductors

1. Characteristics and Applications

Variable inductors allow for adjustable inductance values, making them useful in tuning circuits and applications where frequency response needs to be modified.

2. Common Models and Specifications

While less common than fixed inductors, variable inductors can be found in specialized applications, often custom-designed for specific needs.

C. Integrated Inductors

1. Characteristics and Applications

Integrated inductors combine inductive elements with other components on a single chip, offering compact solutions for power management and RF applications.

2. Common Models and Specifications

Integrated inductors are often found in advanced semiconductor packages, with models varying based on the specific application requirements.

IV. Mainstream Models of Chip Inductors

A. Ferrite Core Inductors

1. Description and Features

Ferrite core inductors are known for their high inductance values and efficiency. They are commonly used in power supply circuits and RF applications due to their ability to handle high frequencies.

2. Popular Models

Murata LQH Series: Offers a wide range of inductance values and is known for its compact size and high performance.

TDK CL Series: Features low DC resistance and high current ratings, making it suitable for power applications.

B. Air Core Inductors

1. Description and Features

Air core inductors are characterized by their lack of a magnetic core, which allows for high-frequency performance and minimal losses. They are often used in RF applications.

2. Popular Models

Coilcraft 0805CS Series: Known for its high self-resonant frequency and low DC resistance, making it ideal for RF circuits.

C. Multilayer Inductors

1. Description and Features

Multilayer inductors utilize thin-film technology to create multiple layers of inductance in a compact form. They are known for their high Q factor and low DC resistance.

2. Popular Models

Vishay IHLP Series: Offers a range of inductance values with excellent thermal performance and low profile.

D. Thin-Film Inductors

1. Description and Features

Thin-film inductors are fabricated using advanced manufacturing techniques, allowing for precise control over inductance values and high-frequency performance.

2. Popular Models

Würth Elektronik WE-MAPI Series: Known for its compact size and high performance in high-frequency applications.

V. Key Specifications and Parameters

A. Inductance Value

The inductance value, measured in henries (H), indicates the inductor's ability to store energy. It is a critical parameter that determines the inductor's suitability for specific applications.

B. DC Resistance (DCR)

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DCR values are preferred for power applications to minimize energy loss.

C. Current Rating

The current rating indicates the maximum current the inductor can handle without overheating. It is essential to select an inductor with a current rating that meets or exceeds the application's requirements.

D. Self-Resonant Frequency (SRF)

The self-resonant frequency is the frequency at which the inductor's inductive reactance equals its capacitive reactance, causing it to resonate. It is crucial for high-frequency applications.

E. Quality Factor (Q)

The quality factor (Q) measures the inductor's efficiency, with higher values indicating lower energy losses. A high Q factor is desirable for RF applications.

F. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature. It is essential for applications where temperature variations are expected.

VI. Applications of Chip Inductors

A. Power Management Circuits

Chip inductors are widely used in power management circuits, including DC-DC converters, where they help regulate voltage and current.

B. RF and Microwave Applications

In RF and microwave applications, chip inductors are used for tuning, filtering, and impedance matching, ensuring optimal signal transmission.

C. Signal Filtering

Inductors play a vital role in signal filtering, removing unwanted frequencies and allowing desired signals to pass through.

D. Energy Storage in DC-DC Converters

Chip inductors store energy in DC-DC converters, enabling efficient power conversion and regulation.

E. Automotive and Industrial Applications

In automotive and industrial settings, chip inductors are used in various applications, including motor control, power supplies, and communication systems.

VII. Trends and Innovations in Chip Inductor Technology

A. Miniaturization and High-Frequency Performance

As electronic devices continue to shrink, the demand for smaller, high-performance chip inductors has increased. Manufacturers are developing innovative designs that maintain performance while reducing size.

B. Integration with Other Components

The trend towards integration is leading to the development of chip inductors that combine multiple functions, such as inductance and capacitance, on a single chip.

C. Advances in Materials and Manufacturing Techniques

New materials and manufacturing techniques are being explored to enhance the performance of chip inductors, including the use of nanomaterials and advanced fabrication methods.

VIII. Conclusion

A. Summary of Key Points

Chip inductors are essential components in modern electronics, offering a range of types and models to suit various applications. Understanding their specifications and characteristics is crucial for selecting the right inductor for specific needs.

B. Future Outlook for Chip Inductors

As technology continues to advance, the demand for high-performance chip inductors will grow. Innovations in design, materials, and manufacturing will drive the development of even more efficient and compact inductors.

C. Final Thoughts on the Importance of Choosing the Right Model

Choosing the right chip inductor is vital for ensuring optimal performance in electronic circuits. By considering factors such as inductance value, current rating, and application requirements, engineers can make informed decisions that enhance the reliability and efficiency of their designs.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Reports

- Market Research Reports on Passive Components

- Industry Analysis on Chip Inductor Trends

C. Manufacturer Specifications and Datasheets

- Murata, TDK, Coilcraft, Vishay, Würth Elektronik product datasheets and specifications.

This comprehensive overview of chip inductors highlights their significance in electronics, the various types available, and the key specifications to consider when selecting them for specific applications. As technology evolves, staying informed about the latest trends and innovations will be crucial for engineers and designers in the field.