Precautions for Inductor Product Training

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As passive components, they store energy in a magnetic field when electrical current flows through them. Given their significance in various applications—from power supplies to radio frequency (RF) circuits—proper training in handling inductor products is essential for ensuring safety and effectiveness in their use. This blog post aims to outline the necessary precautions for inductor product training, providing a comprehensive guide for trainers and trainees alike.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This principle is fundamental to the operation of inductors.

There are several types of inductors, including:

1. **Air Core Inductors**: These inductors use air as the core material and are typically used in high-frequency applications due to their low losses.

2. **Iron Core Inductors**: These inductors use iron as the core material, providing higher inductance values and are commonly used in power applications.

3. **Toroidal Inductors**: Shaped like a doughnut, these inductors minimize electromagnetic interference and are often used in audio and RF applications.

B. Applications of Inductors in Various Industries

Inductors find applications across multiple industries:

1. **Power Supplies**: Inductors are used in switching power supplies to smooth out voltage fluctuations and store energy.

2. **RF Applications**: In RF circuits, inductors are used for tuning and filtering signals, ensuring that only the desired frequencies are transmitted or received.

3. **Filtering and Energy Storage**: Inductors are essential in filter circuits, helping to eliminate unwanted frequencies and store energy for later use.

III. Importance of Safety Precautions

A. Risks Associated with Improper Handling of Inductors

While inductors are generally safe to handle, improper handling can lead to several risks:

1. **Electrical Hazards**: Inductors can store energy, and if discharged improperly, they can cause electrical shocks or damage to equipment.

2. **Physical Injuries**: Inductors can be heavy and cumbersome, leading to potential injuries if not handled correctly.

B. Regulatory Standards and Compliance

Adhering to safety standards is crucial in any training program. Relevant safety standards, such as those set by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), provide guidelines for safe practices in handling electrical components. Compliance with these standards not only ensures safety but also enhances the credibility of the training program.

IV. Pre-Training Preparations

A. Assessing the Training Environment

Before conducting training, it is essential to assess the training environment:

1. **Ensuring a Safe Workspace**: The training area should be free of hazards, with adequate space for participants to move around safely.

2. **Availability of Necessary Tools and Equipment**: Ensure that all required tools, such as multimeters, oscilloscopes, and safety equipment, are available and in good working condition.

B. Identifying the Target Audience

Understanding the target audience is vital for effective training:

1. **Skill Levels and Prior Knowledge**: Assess the participants' existing knowledge and skills to tailor the training content accordingly.

2. **Tailoring Training Content**: Customize the training materials to meet the needs of different skill levels, ensuring that all participants can benefit from the training.

V. Training Content Overview

A. Theoretical Knowledge

A solid foundation in theoretical knowledge is essential for understanding inductors:

1. **Basic Electrical Concepts**: Cover fundamental electrical concepts, such as voltage, current, resistance, and Ohm's law, to ensure all participants have a common understanding.

2. **Inductor Specifications and Ratings**: Discuss the various specifications and ratings of inductors, including inductance value, current rating, and resistance.

B. Practical Skills

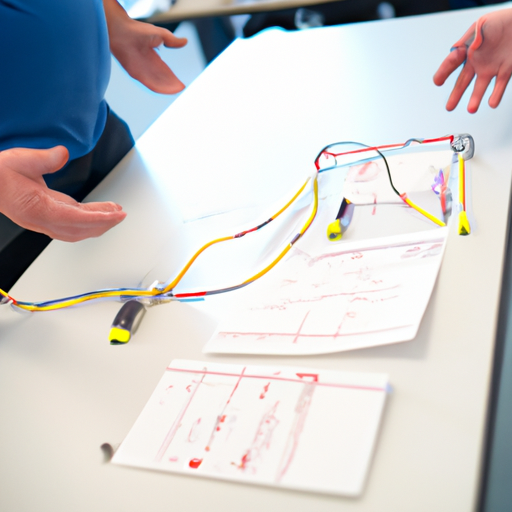

Hands-on experience is crucial for effective training:

1. **Handling and Installation Techniques**: Teach participants the correct methods for handling and installing inductors, emphasizing the importance of proper techniques to avoid damage and ensure safety.

2. **Testing and Troubleshooting Inductors**: Provide practical exercises on how to test inductors using multimeters and oscilloscopes, as well as troubleshooting common issues.

VI. Safety Precautions During Training

A. Personal Protective Equipment (PPE)

Using appropriate PPE is essential for safety during training:

1. **Types of PPE Required**: Participants should wear safety glasses, gloves, and, if necessary, hearing protection when working with inductors.

2. **Importance of Proper Usage**: Emphasize the importance of wearing PPE at all times during practical exercises to minimize the risk of injury.

B. Safe Handling Practices

Establishing safe handling practices is crucial:

1. **Guidelines for Lifting and Moving Inductors**: Teach participants proper lifting techniques to avoid strain or injury, such as bending at the knees and keeping the load close to the body.

2. **Avoiding Static Discharge and Other Electrical Hazards**: Instruct participants on how to handle inductors safely to prevent static discharge, which can damage sensitive components.

C. Emergency Procedures

Preparing for emergencies is a vital aspect of safety training:

1. **Identifying Potential Hazards**: Discuss potential hazards that may arise during training, such as electrical shocks or equipment malfunctions.

2. **Steps to Take in Case of an Accident**: Provide clear instructions on what to do in case of an emergency, including first aid procedures and how to report incidents.

VII. Post-Training Considerations

A. Evaluation of Training Effectiveness

Assessing the effectiveness of the training program is essential for continuous improvement:

1. **Feedback Mechanisms**: Implement feedback forms or surveys to gather participants' opinions on the training content and delivery.

2. **Assessing Knowledge Retention**: Conduct assessments or quizzes to evaluate participants' understanding and retention of the material covered.

B. Continuous Learning and Improvement

Encouraging ongoing education is vital in the ever-evolving field of electronics:

1. **Keeping Up with Industry Advancements**: Encourage participants to stay informed about the latest developments in inductor technology and applications.

2. **Importance of Refresher Courses**: Highlight the value of periodic refresher courses to reinforce knowledge and skills.

VIII. Conclusion

In conclusion, the importance of precautions in inductor product training cannot be overstated. By understanding the principles of inductors, recognizing the risks associated with their handling, and implementing safety measures, trainers can create a safe and effective learning environment. Ongoing education and safety awareness are essential for anyone working with inductors, ensuring that they can harness the full potential of these critical components in modern technology.

IX. References

For further reading and resources, consider exploring the following:

- International Electrotechnical Commission (IEC) standards

- Underwriters Laboratories (UL) guidelines

- Books and articles on inductors and their applications in electronics

By following these guidelines and emphasizing safety, trainers can ensure that participants are well-prepared to handle inductor products confidently and competently.