What are the Product Standards for Capacitor Energy Storage?

I. Introduction

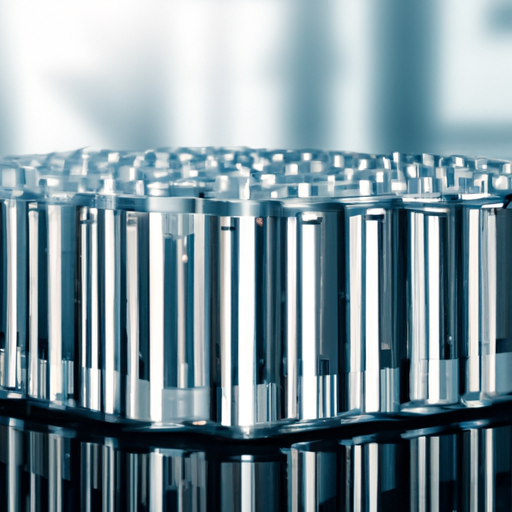

In the rapidly evolving landscape of energy storage technologies, capacitor energy storage systems have emerged as a vital component in various applications, from renewable energy integration to electric vehicles. Capacitors store electrical energy temporarily and release it when needed, making them essential for enhancing power quality and efficiency. However, as the demand for these systems grows, so does the need for robust product standards to ensure their safety, reliability, and performance. This blog post will explore the product standards for capacitor energy storage, their importance, key standards, testing processes, challenges in standardization, and future trends.

II. Understanding Capacitor Energy Storage

A. Basic Principles of Capacitors

Capacitors are passive electrical components that store energy in an electric field. They consist of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied across the plates, an electric field develops, allowing the capacitor to store energy. The amount of energy stored is proportional to the capacitance and the voltage applied.

1. Definition and Functionality

Capacitors serve various functions, including energy storage, filtering, and voltage regulation. In energy storage applications, they can quickly release energy to stabilize voltage levels, support power quality, and provide backup power during short interruptions.

2. Types of Capacitors Used in Energy Storage

Several types of capacitors are utilized in energy storage systems, including electrolytic capacitors, ceramic capacitors, and supercapacitors. Each type has distinct characteristics, such as energy density, power density, and charge/discharge rates, making them suitable for different applications.

B. Applications of Capacitor Energy Storage

Capacitor energy storage systems find applications across various sectors:

1. Renewable Energy Systems

In renewable energy systems, capacitors help manage the intermittent nature of sources like solar and wind. They store excess energy generated during peak production and release it during low production periods, ensuring a stable energy supply.

2. Power Quality Improvement

Capacitors are essential for improving power quality in electrical systems. They can mitigate voltage sags, swells, and harmonics, enhancing the overall reliability of power delivery.

3. Electric Vehicles

In electric vehicles (EVs), capacitors play a crucial role in energy recovery systems, allowing for rapid charging and discharging during acceleration and braking. This enhances the vehicle's efficiency and performance.

4. Industrial Applications

Industries utilize capacitor energy storage for various purposes, including load leveling, reactive power compensation, and backup power for critical processes.

III. Importance of Product Standards

Product standards are essential for ensuring the safety, reliability, and performance of capacitor energy storage systems. They provide a framework for manufacturers, regulators, and consumers to understand the quality and safety of products.

A. Ensuring Safety and Reliability

Standards help mitigate risks associated with capacitor failures, such as overheating, explosions, or electrical hazards. By adhering to established safety protocols, manufacturers can ensure that their products are safe for use in various applications.

B. Promoting Interoperability

With multiple manufacturers producing capacitor energy storage systems, standards promote interoperability between different products. This ensures that systems can work together seamlessly, enhancing overall performance and efficiency.

C. Facilitating Market Access

Compliance with recognized standards can facilitate market access for manufacturers. Products that meet established standards are more likely to gain acceptance in various markets, both domestically and internationally.

D. Enhancing Performance and Efficiency

Standards often include performance benchmarks that manufacturers must meet. This drives innovation and improvement in capacitor technology, leading to more efficient and effective energy storage solutions.

IV. Key Product Standards for Capacitor Energy Storage

Several key product standards govern capacitor energy storage systems, categorized into international, national, and regional standards.

A. International Standards

1. IEC (International Electrotechnical Commission)

The IEC develops international standards for electrical and electronic technologies. Key standards for capacitor energy storage include:

IEC 61071: This standard addresses insulation systems for electrical equipment, ensuring that capacitors can operate safely under various environmental conditions.

IEC 62109: This standard focuses on the safety of power converters, which often incorporate capacitors in their design.

2. ISO (International Organization for Standardization)

ISO 9001: This standard outlines quality management systems, ensuring that manufacturers maintain consistent quality in their products and processes.

B. National Standards

1. ANSI (American National Standards Institute)

ANSI oversees the development of standards in the United States, including those related to capacitor energy storage.

2. UL (Underwriters Laboratories)

UL 810: This standard specifically addresses the safety and performance of capacitors, ensuring that they meet rigorous safety requirements.

C. Regional Standards

1. European Norms (EN)

The European Union has established various norms that govern electrical products, including capacitors, to ensure safety and performance across member states.

2. Japanese Industrial Standards (JIS)

Japan has its own set of industrial standards that govern the manufacturing and testing of capacitors, ensuring that they meet local safety and performance requirements.

V. Testing and Certification Processes

A. Overview of Testing Procedures

Testing is a critical component of ensuring that capacitor energy storage systems meet established standards. Key testing procedures include:

1. Electrical Testing

Electrical testing evaluates the performance of capacitors under various voltage and current conditions, ensuring they can operate safely and effectively.

2. Environmental Testing

Environmental testing assesses how capacitors perform under different environmental conditions, such as temperature, humidity, and exposure to chemicals.

3. Mechanical Testing

Mechanical testing evaluates the physical durability of capacitors, ensuring they can withstand vibrations, shocks, and other mechanical stresses.

B. Certification Bodies

Certification bodies play a crucial role in the testing and certification process. They are responsible for evaluating products against established standards and issuing certifications that demonstrate compliance.

1. Role of Third-Party Testing Organizations

Third-party testing organizations provide unbiased evaluations of capacitor energy storage systems, ensuring that manufacturers adhere to safety and performance standards.

2. Importance of Compliance with Standards

Compliance with established standards is essential for manufacturers to gain consumer trust and ensure the safety and reliability of their products.

VI. Challenges in Standardization

Despite the importance of product standards, several challenges hinder the standardization process for capacitor energy storage systems.

A. Rapid Technological Advancements

The fast pace of technological advancements in capacitor technology can outstrip the development of relevant standards, leading to gaps in regulation and safety.

B. Diverse Applications and Requirements

The wide range of applications for capacitor energy storage systems means that a one-size-fits-all approach to standardization may not be feasible. Different applications may require tailored standards to address specific needs.

C. Global Harmonization of Standards

Achieving global harmonization of standards is a complex challenge, as different countries and regions may have varying regulatory requirements and standards. This can create barriers to international trade and market access.

VII. Future Trends in Capacitor Energy Storage Standards

As the field of capacitor energy storage continues to evolve, several trends are likely to shape the future of product standards.

A. Emerging Technologies

New technologies, such as advanced materials and hybrid energy storage systems, will require the development of new standards to ensure safety and performance.

B. Sustainability and Environmental Considerations

As sustainability becomes a priority, standards will increasingly focus on the environmental impact of capacitor manufacturing and disposal, promoting eco-friendly practices.

C. Integration with Smart Grids and IoT

The integration of capacitor energy storage systems with smart grids and the Internet of Things (IoT) will necessitate new standards to ensure interoperability and security in connected systems.

VIII. Conclusion

In conclusion, product standards for capacitor energy storage systems are essential for ensuring safety, reliability, and performance across various applications. As the demand for these systems continues to grow, industry stakeholders must prioritize compliance with established standards and actively participate in the development of new standards to address emerging technologies and challenges. By doing so, they can contribute to a more efficient, reliable, and sustainable energy future.

IX. References

- IEC Standards: [IEC 61071](https://www.iec.ch) and [IEC 62109](https://www.iec.ch)

- ISO Standards: [ISO 9001](https://www.iso.org)

- ANSI Standards: [ANSI](https://www.ansi.org)

- UL Standards: [UL 810](https://www.ul.com)

- European Norms: [CEN](https://www.cen.eu)

- Japanese Industrial Standards: [JISC](https://www.jisc.go.jp)

This blog post provides a comprehensive overview of the product standards for capacitor energy storage, highlighting their importance, key standards, testing processes, challenges, and future trends. By understanding these aspects, industry stakeholders can better navigate the complexities of capacitor energy storage systems and contribute to their safe and effective implementation.