Understanding Capacitor Housing

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They store electrical energy temporarily and release it when needed, making them essential for various applications, from power supply circuits to audio equipment. However, the performance and reliability of capacitors are significantly influenced by their housing. In this article, we will explore what capacitor housing is, its types, functions, design considerations, and innovations in the field.

II. What is Capacitor Housing?

A. Definition and Purpose

Capacitor housing refers to the protective casing that encases the internal components of a capacitor. Its primary purpose is to safeguard the capacitor's internal elements from environmental factors, mechanical stress, and electrical interference. The housing also plays a vital role in ensuring the capacitor operates efficiently and reliably.

B. Types of Capacitor Housings

Capacitor housings come in various shapes and sizes, each designed for specific applications. The most common types include:

1. **Cylindrical**: This is the most recognizable form of capacitor housing, often used for electrolytic capacitors. Its cylindrical shape allows for efficient use of space and is suitable for high-capacitance applications.

2. **Rectangular**: Rectangular housings are typically used for film and ceramic capacitors. They provide a compact design that can be easily mounted on circuit boards.

3. **Surface Mount**: Surface mount housings are designed for modern electronic devices where space is at a premium. These housings allow capacitors to be mounted directly onto the surface of a printed circuit board (PCB), facilitating automated assembly processes.

C. Materials Used in Capacitor Housing

The choice of material for capacitor housing is critical, as it affects the capacitor's performance and durability. Common materials include:

1. **Plastic**: Often used for low-cost capacitors, plastic housings provide adequate protection against moisture and dust while being lightweight.

2. **Metal**: Metal housings offer superior protection and thermal management, making them suitable for high-performance applications. They can also provide better electrical shielding.

3. **Ceramic**: Ceramic housings are used for specific types of capacitors, such as ceramic capacitors, where the housing itself can contribute to the capacitor's electrical properties.

III. Functions of Capacitor Housing

Capacitor housing serves several essential functions that contribute to the overall performance and reliability of the capacitor:

A. Protection of Internal Components

The primary function of capacitor housing is to protect the internal components from physical damage, moisture, dust, and other environmental factors. This protection is crucial for maintaining the capacitor's performance over time.

B. Thermal Management

Capacitors can generate heat during operation, especially in high-frequency applications. Proper housing design helps dissipate heat, preventing overheating and ensuring the capacitor operates within its specified temperature range.

C. Electrical Insulation

Capacitor housings provide electrical insulation, preventing short circuits and ensuring safe operation. This insulation is particularly important in high-voltage applications where the risk of electrical breakdown is significant.

D. Mechanical Support and Stability

The housing provides mechanical support, ensuring that the internal components remain stable during operation. This stability is vital for maintaining the capacitor's performance and preventing failure due to mechanical stress.

IV. Design Considerations for Capacitor Housing

When designing capacitor housing, several factors must be considered to ensure optimal performance:

A. Size and Form Factor

The size and form factor of the housing must align with the intended application. For instance, compact designs are essential for portable devices, while larger housings may be necessary for high-capacitance applications.

B. Environmental Factors

Capacitor housings must be designed to withstand various environmental conditions, including temperature fluctuations, humidity, and exposure to chemicals. Selecting appropriate materials and sealing methods is crucial for ensuring longevity.

C. Electrical Characteristics

The housing must accommodate the electrical characteristics of the capacitor, including voltage rating and capacitance. This consideration ensures that the housing does not interfere with the capacitor's performance.

D. Manufacturing Processes and Techniques

The manufacturing process used to create the housing can impact its quality and performance. Techniques such as injection molding for plastic housings or stamping for metal housings must be carefully selected to meet the desired specifications.

V. Types of Capacitor Housing in Detail

A. Electrolytic Capacitor Housing

Electrolytic capacitors are widely used in power supply applications due to their high capacitance values. Their cylindrical housing is typically made of aluminum, providing excellent protection and thermal management. These capacitors are commonly found in audio equipment, power amplifiers, and power supply circuits.

B. Ceramic Capacitor Housing

Ceramic capacitors are known for their stability and reliability. Their rectangular housing is often made of ceramic material, which contributes to their electrical properties. These capacitors are commonly used in high-frequency applications, such as RF circuits and decoupling applications.

C. Film Capacitor Housing

Film capacitors are characterized by their use of plastic film as the dielectric material. Their rectangular housing is designed for low-loss applications, making them suitable for audio and signal processing circuits. The housing material is typically a type of plastic that provides good insulation and thermal stability.

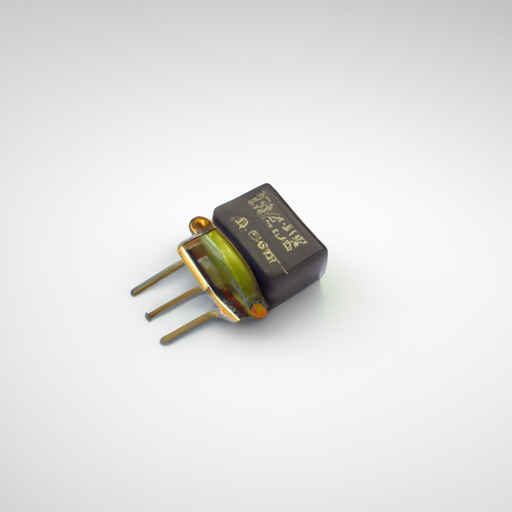

D. Tantalum Capacitor Housing

Tantalum capacitors are known for their high capacitance in a small package. Their housing is typically made of tantalum metal, providing excellent protection and electrical performance. These capacitors are commonly used in portable electronics and military applications due to their reliability and compact size.

VI. The Role of Capacitor Housing in Performance

A. Impact on Lifespan and Reliability

The quality of capacitor housing directly affects the lifespan and reliability of the capacitor. Poorly designed or manufactured housings can lead to premature failure, while high-quality housings can enhance the capacitor's longevity.

B. Influence on Electrical Performance

The housing can influence the electrical performance of the capacitor, including its equivalent series resistance (ESR) and self-resonant frequency. Proper design and material selection are essential for optimizing these characteristics.

C. Case Studies or Examples of Housing Failures

There have been instances where capacitor housing failures have led to catastrophic results, such as in power supply circuits where overheating caused by inadequate thermal management resulted in component failure. These examples highlight the importance of robust housing design.

VII. Innovations in Capacitor Housing

A. Advances in Materials and Technology

Recent advancements in materials science have led to the development of new housing materials that offer improved performance and durability. For example, the use of advanced polymers and composites can enhance thermal management and electrical insulation.

B. Trends in Design and Manufacturing

The trend towards miniaturization in electronics has driven innovations in capacitor housing design. Manufacturers are increasingly focusing on creating compact, lightweight housings that do not compromise performance.

C. Future Directions for Capacitor Housing Development

As technology continues to evolve, the demand for more efficient and reliable capacitors will drive further innovations in housing design. Future developments may include smart housings that can monitor temperature and performance, providing real-time data for improved reliability.

VIII. Conclusion

In conclusion, capacitor housing plays a vital role in the performance, reliability, and longevity of capacitors in electronic circuits. Understanding the various types of housings, their functions, and design considerations is essential for anyone involved in electronics. As technology advances, the importance of capacitor housing will only continue to grow, making it a critical area for further exploration and understanding.

IX. References

1. "Capacitor Basics: A Beginner's Guide" - Electronics Tutorials

2. "The Role of Capacitor Housing in Electronic Circuits" - Journal of Electronic Materials

3. "Advancements in Capacitor Technology" - IEEE Transactions on Industrial Electronics

4. "Understanding Capacitor Types and Applications" - Electronics Weekly

5. "Materials Science in Capacitor Design" - Materials Today

This comprehensive overview of capacitor housing provides a solid foundation for understanding its significance in electronics. Whether you are a student, engineer, or hobbyist, gaining insight into this topic will enhance your knowledge of electronic components and their applications.