What are the Mainstream Models of Capacitor Equipment?

I. Introduction

Capacitors are fundamental components in electrical engineering, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in electronic circuits. Understanding the different types of capacitors and their associated equipment is essential for engineers and technicians working in the field. This blog post will explore the mainstream models of capacitor equipment, including capacitor banks, testing equipment, discharge units, and charging equipment, while also highlighting emerging trends in capacitor technology.

II. Types of Capacitors

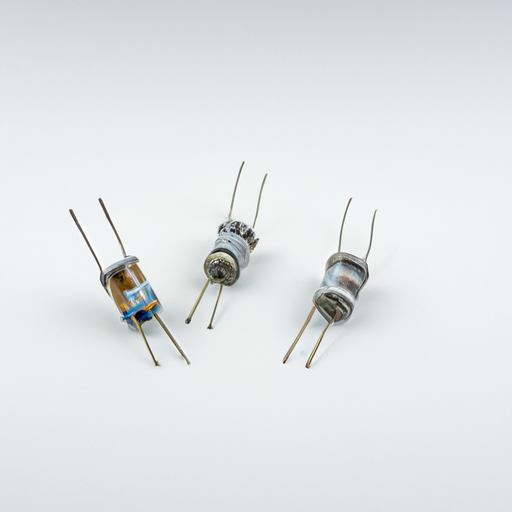

Before delving into capacitor equipment models, it is essential to understand the various types of capacitors available in the market.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte to achieve a larger capacitance per unit volume. They are characterized by their high capacitance values and relatively low voltage ratings. Common applications include power supply filtering, coupling, and decoupling in electronic circuits.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are known for their stability, low losses, and high-frequency performance. These capacitors are widely used in applications such as RF circuits, timing circuits, and decoupling.

C. Film Capacitors

Film capacitors utilize thin plastic films as the dielectric material. They are known for their reliability, low self-inductance, and excellent temperature stability. Film capacitors are commonly used in audio equipment, power electronics, and motor run applications.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, known for their small size and high capacitance. They are often used in applications where space is limited, such as in mobile devices and aerospace electronics. However, they are more expensive than other types of capacitors.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They offer high capacitance values and can charge and discharge rapidly. Supercapacitors are used in applications such as energy harvesting, backup power supplies, and electric vehicles.

III. Capacitor Equipment Models

With a solid understanding of the types of capacitors, we can now explore the various models of capacitor equipment used in the industry.

A. Capacitor Banks

1. Definition and Purpose

Capacitor banks are assemblies of multiple capacitors connected in parallel or series to provide a specific capacitance value. They are primarily used to improve power factor, stabilize voltage levels, and enhance the efficiency of power systems.

2. Types of Capacitor Banks

Fixed Capacitor Banks: These are designed to provide a constant capacitance value and are typically used in applications where the power factor correction requirement is stable.

Automatic Capacitor Banks: These systems can adjust their capacitance in real-time based on the load conditions, making them ideal for dynamic environments where power factor correction is needed.

3. Applications in Power Systems

Capacitor banks are widely used in industrial and commercial power systems to reduce energy costs, improve voltage stability, and enhance the overall efficiency of electrical networks.

B. Capacitor Test Equipment

1. Importance of Testing Capacitors

Testing capacitors is crucial to ensure their reliability and performance. Faulty capacitors can lead to equipment failure, increased energy consumption, and safety hazards.

2. Types of Testing Equipment

Capacitance Meters: These devices measure the capacitance value of capacitors, helping technicians verify if they meet specified ratings.

Insulation Resistance Testers: These testers evaluate the insulation quality of capacitors, ensuring they can withstand operational voltages without leakage.

Power Factor Testers: These instruments measure the power factor of capacitors, providing insights into their efficiency and performance.

3. Key Features and Specifications

When selecting capacitor test equipment, key features to consider include measurement range, accuracy, ease of use, and safety features. High-quality testing equipment is essential for maintaining the integrity of capacitor systems.

C. Capacitor Discharge Equipment

1. Purpose and Importance

Capacitor discharge equipment is used to safely discharge capacitors before maintenance or replacement. This is critical to prevent electrical shock and ensure the safety of technicians.

2. Types of Discharge Equipment

Manual Discharge Units: These are simple devices that allow technicians to discharge capacitors manually using resistive loads.

Automatic Discharge Units: These systems can automatically discharge capacitors to a safe level, providing an added layer of safety.

3. Safety Considerations

Safety is paramount when working with capacitors, as they can store significant amounts of energy. Proper discharge equipment and procedures are essential to prevent accidents.

D. Capacitor Charging Equipment

1. Overview of Charging Equipment

Capacitor charging equipment is used to charge capacitors to their rated voltage levels. This equipment is essential for preparing capacitors for operation in various applications.

2. Types of Charging Equipment

AC Charging Units: These units provide alternating current to charge capacitors, commonly used in power systems.

DC Charging Units: These units supply direct current for charging capacitors, often used in electronic applications.

3. Applications and Use Cases

Charging equipment is used in various industries, including power generation, telecommunications, and consumer electronics, to ensure capacitors are charged safely and efficiently.

IV. Emerging Trends in Capacitor Technology

As technology advances, several trends are shaping the future of capacitor equipment.

A. Advancements in Materials

New materials are being developed to enhance the performance and reliability of capacitors. For example, advancements in dielectric materials can lead to higher capacitance values and improved temperature stability.

B. Miniaturization of Capacitor Equipment

The trend towards miniaturization is driving the development of smaller and more efficient capacitor equipment. This is particularly important in consumer electronics, where space is at a premium.

C. Integration with Renewable Energy Systems

Capacitors are increasingly being integrated into renewable energy systems, such as solar and wind power, to improve energy storage and power quality.

D. Smart Capacitor Solutions

The rise of smart technology is leading to the development of intelligent capacitor solutions that can monitor and adjust their performance in real-time, enhancing efficiency and reliability.

V. Conclusion

In summary, capacitors are vital components in electrical engineering, and understanding the various types and models of capacitor equipment is essential for professionals in the field. From capacitor banks to testing and charging equipment, each model serves a specific purpose in ensuring the reliability and efficiency of electrical systems. As technology continues to evolve, emerging trends in capacitor technology will shape the future of energy storage and management, making it crucial for engineers and technicians to stay informed about these developments.

VI. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

- Online Resources

By understanding the mainstream models of capacitor equipment and their applications, professionals can make informed decisions that enhance the performance and safety of electrical systems.