What are the Manufacturing Processes of the Latest Capacitor Manufacturers?

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that can release energy quickly when needed. They play a crucial role in various applications, from power supply circuits to signal processing in communication devices. As technology advances, the demand for capacitors has surged, leading to a dynamic capacitor manufacturing industry that continually innovates to meet the needs of modern electronics. This article explores the manufacturing processes of the latest capacitor manufacturers, highlighting the types of capacitors, the stages of manufacturing, and the innovations shaping the industry.

II. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

A. Ceramic Capacitors

These capacitors are widely used due to their small size and high capacitance values. They are often found in high-frequency applications.

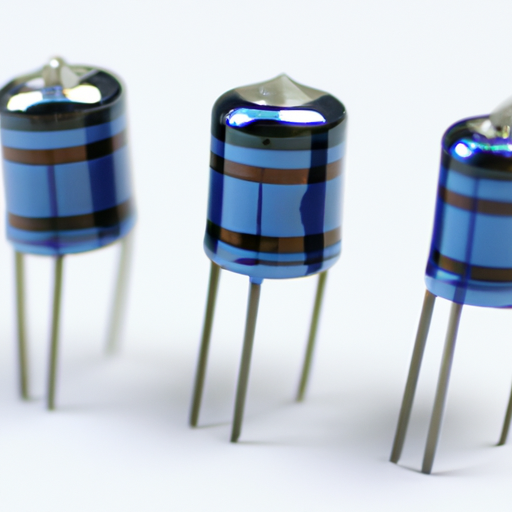

B. Electrolytic Capacitors

Known for their high capacitance, electrolytic capacitors are commonly used in power supply circuits. They are polarized, meaning they have a positive and negative terminal.

C. Film Capacitors

Film capacitors are known for their stability and reliability. They are often used in audio applications and power electronics.

D. Tantalum Capacitors

These capacitors offer high capacitance in a small package and are used in applications where space is limited, such as in mobile devices.

E. Supercapacitors

Supercapacitors, or ultracapacitors, provide high energy density and are used in applications requiring rapid charge and discharge cycles, such as in regenerative braking systems.

F. Comparison of Different Types and Their Applications

Each type of capacitor has unique properties that make it suitable for specific applications, from consumer electronics to industrial machinery.

III. Overview of the Manufacturing Process

The manufacturing of capacitors involves several critical stages:

A. General Stages of Capacitor Manufacturing

1. **Material Selection**: Choosing the right materials is crucial for performance.

2. **Component Fabrication**: This involves creating the individual components of the capacitor.

3. **Assembly**: The components are assembled into the final product.

4. **Testing and Quality Control**: Rigorous testing ensures that the capacitors meet industry standards.

B. Importance of Precision and Quality in Manufacturing

Precision in manufacturing is vital, as even minor defects can lead to failures in electronic devices. Quality control measures are implemented at every stage to ensure reliability.

IV. Material Selection

A. Dielectric Materials

1. **Types and Properties**: Dielectric materials, such as ceramic, polyester, and tantalum oxide, are selected based on their electrical properties.

2. **Recent Advancements in Dielectric Materials**: Innovations in materials science have led to the development of new dielectrics that enhance performance and reduce size.

B. Conductive Materials

1. **Metals Used in Capacitor Manufacturing**: Common conductive materials include aluminum, tantalum, and copper.

2. **Innovations in Conductive Materials**: Research into new alloys and coatings is ongoing to improve conductivity and reduce costs.

V. Component Fabrication

A. Ceramic Capacitors

1. **Powder Preparation**: The process begins with the preparation of ceramic powders.

2. **Pressing and Sintering**: The powders are pressed into shape and then sintered at high temperatures to form a solid dielectric.

3. **Electrode Application**: Electrodes are applied to the ceramic body, completing the capacitor.

B. Electrolytic Capacitors

1. **Anode Foil Preparation**: Aluminum or tantalum foils are prepared to serve as the anode.

2. **Electrolyte Application**: An electrolyte is applied to the anode, creating a dielectric layer.

3. **Sealing and Packaging**: The capacitor is sealed to protect it from environmental factors.

C. Film Capacitors

1. **Film Production**: Thin films of dielectric material are produced.

2. **Metallization Process**: A conductive layer is applied to the film.

3. **Winding and Cutting**: The film is wound into a roll and cut to size.

D. Tantalum Capacitors

1. **Tantalum Powder Preparation**: Tantalum powder is processed to create the anode.

2. **Anode Formation**: The powder is compacted and sintered to form the anode.

3. **Insulation and Electrolyte Application**: An insulating layer is applied, followed by the electrolyte.

E. Supercapacitors

1. **Electrode Material Preparation**: Carbon-based materials are prepared for the electrodes.

2. **Assembly of Electrodes and Separators**: The electrodes are assembled with separators to prevent short circuits.

VI. Assembly Process

A. Automated vs. Manual Assembly

Modern capacitor manufacturing often employs automated assembly lines to enhance efficiency and precision. However, some processes still require manual intervention for quality assurance.

B. Techniques Used in Assembly

Techniques such as surface mount technology (SMT) and through-hole technology are commonly used in the assembly of capacitors.

C. Importance of Cleanroom Environments

Cleanroom environments are essential in capacitor manufacturing to prevent contamination that could affect performance.

VII. Testing and Quality Control

A. Types of Tests Conducted

1. **Electrical Testing**: Capacitors undergo electrical testing to ensure they meet specifications.

2. **Environmental Testing**: Tests simulate various environmental conditions to assess reliability.

B. Quality Assurance Measures

Manufacturers implement strict quality assurance measures, including statistical process control (SPC) and failure mode effects analysis (FMEA).

C. Certification and Compliance with Industry Standards

Compliance with industry standards, such as ISO and IEC, is crucial for ensuring product quality and safety.

VIII. Innovations in Capacitor Manufacturing

A. Advances in Technology

1. **Automation and Robotics**: The use of robotics in manufacturing has increased efficiency and reduced human error.

2. **Smart Manufacturing**: IoT and AI technologies are being integrated into manufacturing processes for real-time monitoring and optimization.

B. Sustainable Practices

1. **Eco-Friendly Materials**: Manufacturers are exploring biodegradable and recyclable materials to reduce environmental impact.

2. **Waste Reduction Techniques**: Lean manufacturing principles are being adopted to minimize waste.

C. Future Trends in Capacitor Manufacturing

The future of capacitor manufacturing will likely see further advancements in materials science, automation, and sustainability practices.

IX. Case Studies of Leading Capacitor Manufacturers

A. Overview of Notable Manufacturers

1. **Manufacturer A**: Known for its innovative processes, Manufacturer A has developed a new type of ceramic capacitor that offers higher capacitance in a smaller footprint.

2. **Manufacturer B**: This company has made significant strides in sustainability, using eco-friendly materials and processes to reduce its carbon footprint.

3. **Manufacturer C**: With a focus on technological advancements, Manufacturer C has integrated AI into its manufacturing processes for improved efficiency.

B. Comparison of Manufacturing Processes Among Leading Companies

While each manufacturer has its unique processes, common trends include the use of automation, emphasis on quality control, and a commitment to sustainability.

X. Conclusion

The manufacturing processes of capacitors are complex and continually evolving to meet the demands of modern electronics. With advancements in materials, automation, and sustainability, the capacitor manufacturing industry is poised for significant growth. As technology continues to advance, the importance of innovation in manufacturing processes will remain critical to ensuring the reliability and performance of capacitors in electronic devices.

XI. References

A comprehensive list of sources and further reading materials would be included here to support the information presented in the article.

---

This blog post provides an in-depth look at the manufacturing processes of the latest capacitor manufacturers, covering various aspects from types of capacitors to innovations in the industry.