What are the Latest Capacitor Models and Equipment Component Purchasing Models?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling signal processing in communication devices. As technology advances, the demand for more efficient and compact capacitors has led to the development of innovative models and purchasing strategies. This article explores the latest capacitor models and the evolving equipment component purchasing models, providing insights into the current trends shaping the electronics industry.

II. Overview of Capacitor Technology

A. Brief History of Capacitors

The concept of capacitance dates back to the 18th century, with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has evolved significantly, leading to the development of various types of capacitors tailored for specific applications. Today, capacitors are integral to modern electronics, with advancements in materials and manufacturing processes enhancing their performance and reliability.

B. Types of Capacitors

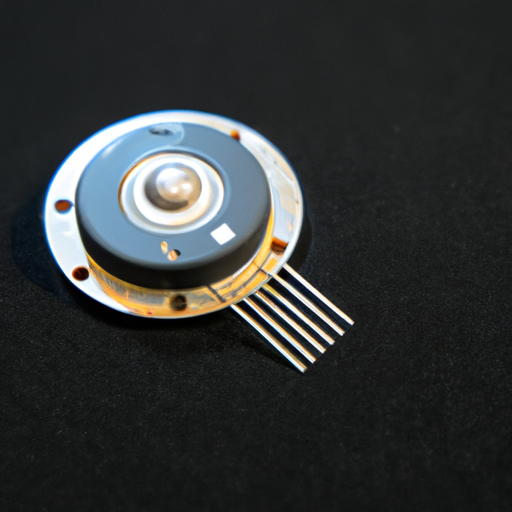

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications. They are available in various capacitance values and voltage ratings.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are commonly used in power supply circuits. They are polarized, meaning they must be connected in the correct direction to function properly.

3. **Film Capacitors**: Made from plastic films, these capacitors are known for their low ESR and high voltage ratings. They are often used in audio applications and power electronics.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance in a small package. They are often used in portable electronics and medical devices due to their reliability.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems.

C. Key Specifications and Parameters

Understanding the specifications of capacitors is essential for selecting the right component for a specific application. Key parameters include:

1. **Capacitance**: Measured in farads (F), capacitance indicates the amount of charge a capacitor can store.

2. **Voltage Rating**: This specifies the maximum voltage a capacitor can handle without breaking down.

3. **Equivalent Series Resistance (ESR)**: A measure of the resistance a capacitor presents to alternating current, lower ESR values indicate better performance.

4. **Temperature Coefficient**: This indicates how a capacitor's capacitance changes with temperature, which is crucial for applications in varying environmental conditions.

III. Latest Capacitor Models

A. Innovations in Capacitor Technology

Recent advancements in capacitor technology have led to the development of several innovative models:

1. **High-Capacitance Capacitors**: Manufacturers are producing capacitors with higher capacitance values, allowing for more energy storage in smaller packages. This is particularly beneficial for applications in renewable energy systems and electric vehicles.

2. **Miniaturization and Surface-Mount Technology (SMT)**: The trend towards smaller electronic devices has driven the development of miniaturized capacitors that can be mounted directly onto circuit boards, saving space and improving performance.

3. **Enhanced Performance Capacitors**: New materials and designs have led to capacitors with low ESR and high ripple current capabilities, making them suitable for demanding applications such as power supplies and audio equipment.

B. Notable Manufacturers and Their Latest Offerings

Several manufacturers are at the forefront of capacitor innovation:

1. **Murata Manufacturing Co.**: Known for its advanced ceramic capacitors, Murata has introduced high-capacitance models that cater to the growing demand for compact electronic devices.

2. **KEMET Corporation**: KEMET offers a wide range of capacitors, including tantalum and film capacitors, with a focus on high reliability and performance in automotive and industrial applications.

3. **Vishay Intertechnology**: Vishay is recognized for its diverse capacitor portfolio, including aluminum electrolytic and film capacitors, designed for high-performance applications.

4. **Panasonic Corporation**: Panasonic has developed a range of supercapacitors and electrolytic capacitors that are ideal for energy storage solutions and consumer electronics.

C. Applications of New Capacitor Models

The latest capacitor models find applications across various industries:

1. **Consumer Electronics**: High-capacitance and miniaturized capacitors are essential for smartphones, tablets, and wearable devices, where space is at a premium.

2. **Automotive Industry**: Capacitors play a critical role in electric vehicles, powering systems such as regenerative braking and energy storage.

3. **Renewable Energy Systems**: Capacitors are used in solar inverters and wind turbines to manage energy flow and improve efficiency.

4. **Industrial Automation**: Enhanced performance capacitors are vital in automation systems, ensuring reliable operation in demanding environments.

IV. Equipment Component Purchasing Models

A. Traditional Purchasing Models

1. **Direct Purchasing from Manufacturers**: Many companies prefer to buy capacitors directly from manufacturers to ensure quality and reliability. This model often involves negotiating contracts and bulk purchasing agreements.

2. **Distributors and Wholesalers**: Distributors play a crucial role in the supply chain, providing access to a wide range of capacitor models and facilitating smaller orders for manufacturers and engineers.

B. Emerging Purchasing Models

1. **E-commerce Platforms and Online Marketplaces**: The rise of e-commerce has transformed the way companies purchase capacitors. Online platforms allow for easy comparison of prices and specifications, making it simpler for buyers to find the right components.

2. **Subscription-Based Models**: Some suppliers offer subscription services that provide regular deliveries of capacitors based on the buyer's needs, helping to streamline inventory management.

3. **Just-in-Time (JIT) Inventory Systems**: JIT systems minimize inventory costs by ensuring that components are delivered only when needed, reducing waste and improving efficiency.

C. Factors Influencing Purchasing Decisions

Several factors influence how companies approach capacitor purchasing:

1. **Cost Considerations**: Price remains a significant factor, with companies seeking the best value for their investment.

2. **Lead Times and Availability**: The ability to obtain components quickly is crucial, especially in industries with tight production schedules.

3. **Quality Assurance and Certifications**: Buyers often look for components that meet specific quality standards and certifications to ensure reliability.

4. **Supplier Relationships and Support**: Strong relationships with suppliers can lead to better pricing, support, and access to new technologies.

V. Trends in Capacitor Purchasing

A. Shift Towards Sustainability and Eco-Friendly Components

As environmental concerns grow, there is a noticeable shift towards sustainable and eco-friendly capacitor options. Manufacturers are exploring materials and processes that reduce environmental impact, appealing to companies focused on sustainability.

B. Increasing Demand for Customized Solutions

With the rise of specialized applications, there is an increasing demand for customized capacitor solutions. Manufacturers are responding by offering tailored products that meet specific performance requirements.

C. The Role of Technology in Purchasing Decisions

1. **Use of AI and Machine Learning for Inventory Management**: Companies are leveraging AI to optimize inventory levels and predict demand, ensuring they have the right components on hand.

2. **Data Analytics for Demand Forecasting**: Advanced analytics tools help companies forecast demand more accurately, allowing for better planning and purchasing strategies.

D. Impact of Global Supply Chain Dynamics on Purchasing

Global supply chain challenges, such as disruptions caused by the COVID-19 pandemic, have forced companies to reevaluate their purchasing strategies. Many are diversifying their supplier base and exploring local sourcing options to mitigate risks.

VI. Conclusion

Understanding the latest capacitor models and evolving purchasing strategies is essential for companies operating in the electronics industry. As technology continues to advance, staying informed about innovations in capacitor design and the factors influencing purchasing decisions will be crucial for maintaining a competitive edge. The future of capacitors and purchasing strategies will likely be shaped by sustainability, customization, and technological advancements, paving the way for more efficient and reliable electronic systems.

VII. References

For further reading and research on capacitors and purchasing models, consider exploring the following sources:

1. Murata Manufacturing Co. - [Website](https://www.murata.com)

2. KEMET Corporation - [Website](https://www.kemet.com)

3. Vishay Intertechnology - [Website](https://www.vishay.com)

4. Panasonic Corporation - [Website](https://www.panasonic.com)

5. Industry publications and journals on electronics and component purchasing trends.

By keeping abreast of these developments, professionals can make informed decisions that enhance their projects and contribute to the advancement of technology.