The Role of Air Conditioning Capacitor Products in Practical Applications

I. Introduction

Air conditioning systems are essential for maintaining comfortable indoor environments, especially in regions with extreme temperatures. At the heart of these systems lies a crucial component known as the capacitor. Air conditioning capacitors play a vital role in the efficiency and reliability of HVAC (heating, ventilation, and air conditioning) systems. This article aims to explore the significance of air conditioning capacitors, their types, practical applications, benefits, challenges, and future trends in technology.

II. Understanding Air Conditioning Capacitors

A. What is a Capacitor?

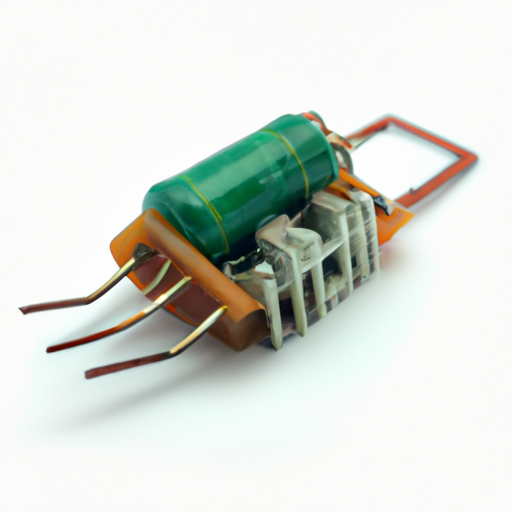

A capacitor is an electrical component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, the capacitor charges, storing energy in the electric field between the plates. When the voltage is removed, the capacitor can discharge this stored energy, providing a burst of power when needed.

1. Basic Electrical Principles

Capacitors operate based on the principle of capacitance, which is the ability of a system to store an electric charge. The unit of capacitance is the farad (F), and capacitors can be classified based on their capacitance values, voltage ratings, and dielectric materials.

2. Types of Capacitors Used in Air Conditioning

In air conditioning systems, two primary types of capacitors are commonly used: start capacitors and run capacitors. Each type serves a distinct purpose in the operation of the system.

B. Function of Capacitors in Air Conditioning Systems

Air conditioning capacitors serve several critical functions:

1. Energy Storage

Capacitors store electrical energy, which can be released quickly to provide the necessary power to start the compressor or fan motor in an air conditioning unit. This energy storage capability is essential for the initial surge of power required to overcome inertia and get the motor running.

2. Voltage Regulation

Capacitors help regulate voltage levels within the system, ensuring that the electrical components receive a stable and consistent voltage supply. This regulation is crucial for the efficient operation of the HVAC system.

3. Phase Shift in AC Motors

In alternating current (AC) motors, capacitors create a phase shift between the current and voltage, which improves the motor's efficiency and performance. This phase shift is particularly important in single-phase motors, commonly used in residential air conditioning systems.

III. Types of Capacitors in Air Conditioning

A. Start Capacitors

Start capacitors are designed to provide a temporary boost of energy to the motor during startup. They are typically used in systems with single-phase motors.

1. Purpose and Function

The primary purpose of a start capacitor is to increase the starting torque of the motor, allowing it to overcome initial resistance and start running. Once the motor reaches a certain speed, the start capacitor is disconnected from the circuit.

2. Characteristics and Specifications

Start capacitors are usually rated for a higher capacitance value and a shorter operational duration compared to run capacitors. They are designed to handle the high inrush current during startup.

B. Run Capacitors

Run capacitors are used to improve the efficiency of the motor during its normal operation.

1. Purpose and Function

Run capacitors remain in the circuit while the motor is running, providing continuous voltage support and improving the motor's efficiency. They help maintain a consistent power supply, reducing energy consumption.

2. Characteristics and Specifications

Run capacitors typically have lower capacitance values than start capacitors and are designed for continuous operation. They are rated for longer life and stability under varying temperature conditions.

C. Dual Run Capacitors

Dual run capacitors combine the functions of both start and run capacitors into a single unit.

1. Combination of Start and Run Functions

These capacitors are designed to provide both the initial boost of energy needed for startup and the continuous support required during operation. This dual functionality simplifies installation and reduces the number of components in the system.

2. Applications and Benefits

Dual run capacitors are commonly used in residential and commercial HVAC systems, offering a compact solution that enhances efficiency and reliability.

IV. Practical Applications of Air Conditioning Capacitors

A. Residential Air Conditioning Systems

In residential settings, air conditioning capacitors play a crucial role in ensuring the efficiency and performance of HVAC systems.

1. Role in Efficiency and Performance

Capacitors help optimize the performance of air conditioning units by providing the necessary power for motors to start and run efficiently. This optimization leads to improved cooling performance and comfort for occupants.

2. Impact on Energy Consumption

By enhancing the efficiency of the system, capacitors contribute to lower energy consumption, resulting in reduced utility bills for homeowners. Efficient air conditioning systems also have a smaller environmental footprint.

B. Commercial HVAC Systems

In commercial applications, the importance of air conditioning capacitors is magnified due to the scale and complexity of the systems involved.

1. Importance in Large-Scale Applications

Commercial HVAC systems often require multiple motors and components to operate simultaneously. Capacitors ensure that each motor receives the necessary power to function effectively, maintaining a comfortable environment for employees and customers.

2. Reliability and Maintenance Considerations

The reliability of capacitors in commercial systems is critical, as any failure can lead to significant downtime and loss of productivity. Regular maintenance and monitoring of capacitor health are essential to prevent unexpected failures.

C. Industrial Applications

In industrial settings, air conditioning capacitors are used in heavy-duty air conditioning units and process cooling systems.

1. Use in Heavy-Duty Air Conditioning Units

Industrial air conditioning systems often operate under demanding conditions, requiring robust capacitors that can handle high loads and extreme temperatures. Capacitors play a vital role in ensuring the reliability and efficiency of these systems.

2. Role in Process Cooling Systems

In manufacturing processes that require precise temperature control, capacitors help maintain the performance of cooling systems, ensuring that products are produced under optimal conditions.

V. Benefits of Using Quality Capacitors

Investing in high-quality air conditioning capacitors offers several benefits:

A. Enhanced System Performance

Quality capacitors improve the overall performance of HVAC systems, leading to better cooling efficiency and comfort.

B. Increased Lifespan of HVAC Equipment

By providing stable voltage and reducing stress on motors, quality capacitors can extend the lifespan of HVAC equipment, reducing the need for costly replacements.

C. Cost-Effectiveness and Energy Savings

Efficient capacitors contribute to lower energy consumption, resulting in significant cost savings over time. This cost-effectiveness makes them a worthwhile investment for homeowners and businesses alike.

D. Reduced Risk of System Failures

High-quality capacitors are less prone to failure, reducing the risk of unexpected breakdowns and the associated costs of repairs and downtime.

VI. Challenges and Considerations

A. Common Issues with Air Conditioning Capacitors

Despite their importance, air conditioning capacitors can face several challenges:

1. Overheating

Capacitors can overheat due to excessive voltage or prolonged operation, leading to failure. Proper sizing and installation are crucial to prevent overheating.

2. Aging and Degradation

Over time, capacitors can degrade due to environmental factors, leading to reduced performance. Regular inspections and timely replacements are essential to maintain system efficiency.

B. Importance of Regular Maintenance

Regular maintenance of HVAC systems, including capacitor checks, is vital to ensure optimal performance and prevent unexpected failures.

C. Selecting the Right Capacitor for Specific Applications

Choosing the right capacitor for a specific application is critical. Factors such as capacitance value, voltage rating, and environmental conditions must be considered to ensure compatibility and performance.

VII. Future Trends in Air Conditioning Capacitor Technology

A. Innovations in Capacitor Design and Materials

Advancements in materials and design are leading to the development of more efficient and durable capacitors. These innovations promise to enhance the performance and reliability of HVAC systems.

B. Integration with Smart HVAC Systems

As HVAC systems become increasingly integrated with smart technology, capacitors will play a crucial role in ensuring efficient operation and energy management.

C. Environmental Considerations and Sustainability

The push for sustainability is driving the development of eco-friendly capacitors that minimize environmental impact while maintaining performance.

VIII. Conclusion

Air conditioning capacitors are essential components that significantly impact the efficiency and reliability of HVAC systems. From residential units to large commercial and industrial applications, capacitors play a vital role in ensuring optimal performance and energy savings. As technology continues to evolve, the importance of selecting quality capacitors and maintaining them properly cannot be overstated. By understanding the role of air conditioning capacitors, homeowners and businesses can make informed decisions that enhance their HVAC systems' efficiency and longevity. Proper maintenance and selection of capacitors will ensure that air conditioning systems continue to provide comfort and reliability for years to come.