Current Situation of the Capacitor Manufacturer Industry

I. Introduction

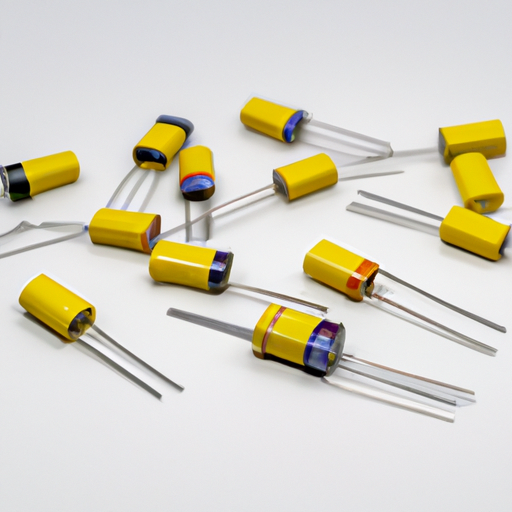

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and current flow. They play a critical role in various applications, from consumer electronics to automotive systems, making them indispensable in modern technology. The capacitor manufacturing industry has evolved significantly over the years, adapting to technological advancements and changing market demands. This article aims to provide an in-depth analysis of the current state of the capacitor manufacturing industry, exploring its historical context, market dynamics, technological innovations, challenges, and future outlook.

II. Historical Context

The history of capacitor technology dates back to the 18th century, with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has evolved, leading to the development of various types of capacitors, including ceramic, electrolytic, and tantalum capacitors. The capacitor manufacturing industry has seen significant growth, particularly in the latter half of the 20th century, driven by the rapid expansion of the electronics sector.

Key milestones in the industry include the introduction of surface-mount technology (SMT) in the 1980s, which allowed for smaller and more efficient capacitor designs. The 21st century has brought further advancements, such as the development of supercapacitors and the use of new materials that enhance performance and reliability.

III. Market Overview

A. Global Market Size and Growth Trends

As of 2023, the global capacitor market is valued at approximately $25 billion, with projections indicating a compound annual growth rate (CAGR) of around 6% over the next five years. This growth is driven by the increasing demand for capacitors in various sectors, including consumer electronics, automotive, and renewable energy.

B. Key Players in the Industry

The capacitor manufacturing industry is characterized by a mix of established players and emerging companies. Major manufacturers such as Murata Manufacturing, Vishay Intertechnology, and KEMET dominate the market, holding significant market shares. However, the rise of startups and smaller companies is fostering innovation and competition, particularly in niche markets.

C. Regional Analysis

The capacitor market is geographically diverse, with significant activity in North America, Europe, and the Asia-Pacific region.

North America: The region is home to several leading manufacturers and benefits from a strong demand for advanced electronic components.

Europe: European manufacturers are focusing on sustainability and eco-friendly practices, aligning with stringent environmental regulations.

Asia-Pacific: This region is the largest market for capacitors, driven by the rapid growth of the electronics industry in countries like China, Japan, and South Korea.

IV. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications.

A. Overview of Different Types of Capacitors

1. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are widely used in consumer electronics and telecommunications.

2. **Electrolytic Capacitors**: These capacitors are favored for their high capacitance values and are commonly found in power supply circuits.

3. **Film Capacitors**: Film capacitors are known for their low losses and high insulation resistance, making them suitable for audio and industrial applications.

4. **Tantalum Capacitors**: Tantalum capacitors offer high capacitance in a small package, making them ideal for space-constrained applications.

5. **Supercapacitors**: These capacitors provide high energy density and are increasingly used in renewable energy systems and electric vehicles.

B. Applications of Each Type in Various Industries

Capacitors find applications across multiple industries:

Consumer Electronics: Capacitors are integral to smartphones, laptops, and home appliances, ensuring stable power supply and signal integrity.

Automotive: In the automotive sector, capacitors are used in power management systems, infotainment, and advanced driver-assistance systems (ADAS).

Industrial: Capacitors play a crucial role in motor drives, power conditioning, and automation systems.

Telecommunications: Capacitors are essential for signal processing and power supply in communication devices.

V. Technological Innovations

A. Recent Advancements in Capacitor Technology

The capacitor manufacturing industry is witnessing several technological innovations:

1. **Miniaturization and High-Capacity Designs**: Manufacturers are developing smaller capacitors with higher capacitance values to meet the demands of compact electronic devices.

2. **Development of New Materials**: The use of advanced materials, such as graphene and organic polymers, is enhancing capacitor performance and reliability.

3. **Enhanced Performance Characteristics**: Innovations in dielectric materials are leading to capacitors with improved temperature stability and lower equivalent series resistance (ESR).

B. Impact of Technology on Manufacturing Processes

Technological advancements are also transforming manufacturing processes:

1. **Automation and Smart Manufacturing**: The integration of automation and smart technologies is improving production efficiency and reducing costs.

2. **Sustainability and Eco-Friendly Practices**: Manufacturers are increasingly adopting sustainable practices, such as recycling and reducing waste, to comply with environmental regulations.

VI. Challenges Facing the Industry

Despite its growth, the capacitor manufacturing industry faces several challenges:

A. Supply Chain Disruptions

Global events, such as the COVID-19 pandemic and geopolitical tensions, have disrupted supply chains, leading to delays and increased costs. Additionally, raw material shortages, particularly for critical components, are impacting production.

B. Competition and Pricing Pressures

The industry is experiencing intense competition, with price wars among manufacturers driving down profit margins. Low-cost producers, particularly from Asia, are challenging established players, forcing them to innovate and differentiate their products.

C. Regulatory Challenges

Manufacturers must navigate a complex landscape of environmental regulations and compliance with international standards. Adapting to these regulations can be costly and time-consuming.

VII. Future Outlook

A. Predictions for Market Growth and Trends

The capacitor market is expected to continue its growth trajectory, driven by increasing demand in emerging technologies such as electric vehicles, renewable energy, and the Internet of Things (IoT). The shift towards more sustainable and energy-efficient solutions will also shape the future of the industry.

B. Potential Areas for Innovation and Development

Future innovations may focus on enhancing energy density, improving thermal stability, and developing capacitors that can operate in extreme conditions. Research into new materials and manufacturing techniques will be crucial for staying competitive.

C. The Role of Capacitors in Emerging Technologies

Capacitors will play a vital role in the development of electric vehicles, where they are used in energy storage systems and regenerative braking. In renewable energy applications, capacitors help stabilize power output and improve efficiency.

VIII. Conclusion

The capacitor manufacturing industry is at a pivotal point, characterized by rapid technological advancements and evolving market dynamics. While challenges such as supply chain disruptions and intense competition persist, the future outlook remains positive, with significant growth opportunities in emerging technologies. Stakeholders in the industry must adapt and innovate to stay ahead in this competitive landscape, ensuring that capacitors continue to play a crucial role in the advancement of modern electronics.

IX. References

1. Smith, J. (2022). "Capacitor Technology: A Historical Perspective." Journal of Electronics.

2. Global Market Insights. (2023). "Capacitor Market Size and Growth Trends."

3. Vishay Intertechnology. (2023). "Capacitor Product Overview."

4. Murata Manufacturing. (2023). "Innovations in Capacitor Technology."

5. KEMET. (2023). "Sustainability in Capacitor Manufacturing."

This blog post provides a comprehensive overview of the current situation of the capacitor manufacturing industry, highlighting its historical context, market dynamics, technological innovations, challenges, and future outlook.