What Product Types Do Film Capacitors Include?

I. Introduction

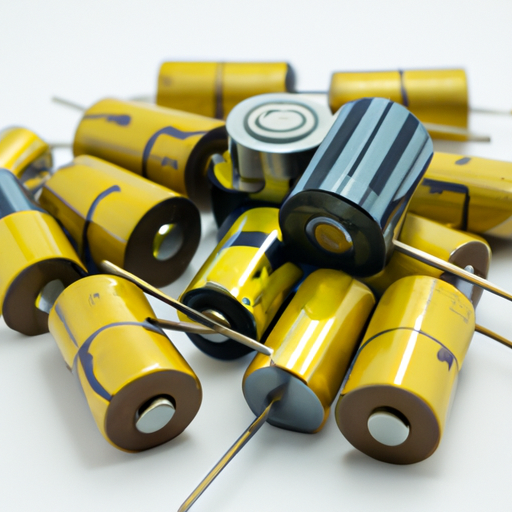

Film capacitors are essential components in modern electronic circuits, known for their reliability and performance. These passive electronic devices store and release electrical energy, playing a crucial role in filtering, coupling, and timing applications. As technology advances, the demand for high-performance capacitors has increased, making it vital to understand the various types of film capacitors available in the market. This article aims to provide an in-depth overview of film capacitors, their construction, types, applications, and their significance in the electronics industry.

II. Basic Principles of Film Capacitors

A. Construction and Materials

Film capacitors are constructed using thin plastic films as dielectric materials, which are sandwiched between conductive electrodes. The choice of materials significantly influences the capacitor's performance characteristics.

1. **Dielectric Materials**: Common dielectric materials used in film capacitors include polyester, polypropylene, polycarbonate, and polystyrene. Each material has unique properties that affect capacitance, voltage rating, and temperature stability.

2. **Electrode Materials**: The electrodes in film capacitors are typically made from aluminum or copper, which are chosen for their excellent conductivity and ability to form a stable interface with the dielectric.

B. Working Principle

The working principle of film capacitors is based on the ability of the dielectric material to store electrical energy in an electric field. When a voltage is applied across the electrodes, an electric field is created, causing positive and negative charges to accumulate on opposite sides of the dielectric. This charge separation allows the capacitor to store energy, which can be released when needed.

C. Advantages of Film Capacitors

Film capacitors offer several advantages over other types of capacitors:

1. **Stability**: They exhibit excellent temperature and voltage stability, making them suitable for a wide range of applications.

2. **Low Losses**: Film capacitors have low equivalent series resistance (ESR), resulting in minimal energy loss during operation.

3. **High Voltage Ratings**: Many film capacitors can handle high voltage levels, making them ideal for power electronics applications.

III. Types of Film Capacitors

Film capacitors can be categorized based on dielectric material, construction, and application.

A. Based on Dielectric Material

1. **Polyester Film Capacitors (Mylar)**: These are widely used due to their cost-effectiveness and decent performance. They are suitable for general-purpose applications but have lower temperature stability compared to other types.

2. **Polypropylene Film Capacitors**: Known for their excellent electrical properties, polypropylene capacitors are often used in audio and high-frequency applications due to their low dielectric losses.

3. **Polycarbonate Film Capacitors**: These capacitors offer high stability and reliability, making them suitable for precision applications. However, they are less common due to their higher cost.

4. **Polystyrene Film Capacitors**: Known for their low dielectric absorption and excellent stability, polystyrene capacitors are often used in timing and coupling applications.

5. **Other Specialty Dielectrics**: Some film capacitors utilize specialty dielectrics, such as fluorinated polymers, which provide unique properties for specific applications.

B. Based on Construction

1. **Metalized Film Capacitors**: These capacitors have a thin layer of metal deposited on the dielectric film, which serves as the electrode. They are compact and have self-healing properties, making them popular in various applications.

2. **Foil Film Capacitors**: In foil capacitors, the electrodes are made from thin metal foils. They typically offer higher current handling capabilities but are bulkier than metalized film capacitors.

C. Based on Application

1. **Power Electronics**: Film capacitors are widely used in power supply circuits, inverters, and converters due to their high voltage ratings and low losses.

2. **Audio Applications**: High-quality film capacitors are essential in audio equipment for coupling and filtering, ensuring minimal signal distortion.

3. **RF Applications**: In radio frequency circuits, film capacitors are used for tuning and filtering, where stability and low losses are critical.

4. **Timing and Coupling Applications**: Film capacitors are often employed in timing circuits and coupling applications, where precise capacitance values are required.

IV. Specialized Film Capacitors

In addition to standard film capacitors, there are specialized types designed for specific applications:

A. High-Voltage Film Capacitors

These capacitors are designed to operate at elevated voltage levels, making them suitable for applications in power electronics and industrial equipment.

B. Motor Run Capacitors

Motor run capacitors are used in single-phase electric motors to improve efficiency and performance. They help maintain a consistent voltage supply during operation.

C. Snubber Capacitors

Snubber capacitors are employed in circuits to suppress voltage spikes and transients, protecting sensitive components from damage.

D. Capacitors for Power Factor Correction

These capacitors are used in industrial applications to improve the power factor of electrical systems, enhancing efficiency and reducing energy costs.

E. Capacitors for Energy Storage

Film capacitors can also be used for energy storage applications, providing a reliable solution for applications requiring rapid charge and discharge cycles.

V. Applications of Film Capacitors

Film capacitors find applications across various industries, including:

A. Consumer Electronics

In consumer electronics, film capacitors are used in audio equipment, televisions, and other devices where high performance and reliability are essential.

B. Industrial Equipment

Film capacitors are employed in industrial machinery for power supply, motor control, and automation systems, ensuring efficient operation.

C. Automotive Applications

In the automotive industry, film capacitors are used in electronic control units, infotainment systems, and electric vehicle applications, contributing to improved performance and reliability.

D. Renewable Energy Systems

Film capacitors play a crucial role in renewable energy systems, such as solar inverters and wind turbines, where they help manage power conversion and storage.

E. Telecommunications

In telecommunications, film capacitors are used in signal processing and filtering applications, ensuring clear and reliable communication.

VI. Comparison with Other Capacitor Types

Understanding the differences between film capacitors and other capacitor types is essential for selecting the right component for a specific application.

A. Film Capacitors vs. Ceramic Capacitors

Ceramic capacitors are smaller and offer higher capacitance values, but they may have lower voltage ratings and stability compared to film capacitors. Film capacitors are preferred in applications requiring high stability and low losses.

B. Film Capacitors vs. Electrolytic Capacitors

Electrolytic capacitors are polarized and typically offer higher capacitance values, but they have limited voltage ratings and can be less reliable over time. Film capacitors are non-polarized and provide better performance in high-frequency applications.

C. Film Capacitors vs. Tantalum Capacitors

Tantalum capacitors offer high capacitance in a small package but can be more expensive and less reliable than film capacitors. Film capacitors are often chosen for applications requiring robustness and stability.

VII. Future Trends in Film Capacitor Technology

As technology continues to evolve, several trends are shaping the future of film capacitor technology:

A. Innovations in Materials

Research is ongoing to develop new dielectric materials that offer improved performance characteristics, such as higher capacitance and better thermal stability.

B. Miniaturization and Integration

The trend towards miniaturization in electronics is driving the development of smaller film capacitors that can be integrated into compact devices without compromising performance.

C. Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on developing eco-friendly materials and production processes for film capacitors.

VIII. Conclusion

Film capacitors are vital components in modern electronics, offering a range of types and applications that cater to various needs. Their stability, low losses, and high voltage ratings make them indispensable in many industries, from consumer electronics to renewable energy systems. Understanding the different types of film capacitors and their applications is crucial for engineers and designers to make informed decisions in their projects. As technology advances, film capacitors will continue to play a significant role in shaping the future of electronic devices.

IX. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

4. Online Resources and Articles

This comprehensive overview of film capacitors highlights their importance and versatility in the electronics industry, providing valuable insights for anyone looking to deepen their understanding of these essential components.