What are the Product Features of Capacitors?

I. Introduction

A. Definition of Capacitors

Capacitors are passive electronic components that store electrical energy in an electric field. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field develops, allowing the capacitor to store energy.

B. Importance of Capacitors in Electronic Circuits

Capacitors play a crucial role in various electronic circuits, serving functions such as energy storage, filtering, coupling, and decoupling signals. They are essential in power supply systems, timing circuits, and audio equipment, among other applications. Their ability to store and release energy quickly makes them invaluable in modern electronics.

C. Overview of the Article

This article will explore the fundamental principles of capacitors, their key product features, specialized characteristics, and applications. Understanding these aspects is vital for selecting the right capacitor for specific electronic needs.

II. Basic Principles of Capacitors

A. How Capacitors Work

1. Charge Storage Mechanism

Capacitors store electrical energy by accumulating charge on their plates. When connected to a power source, electrons flow onto one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. The amount of charge a capacitor can store is determined by its capacitance.

2. Capacitance and Its Measurement

Capacitance is the measure of a capacitor's ability to store charge, defined as the ratio of the electric charge (Q) stored on one plate to the voltage (V) across the plates. It is measured in farads (F), with common subunits including microfarads (µF) and picofarads (pF).

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

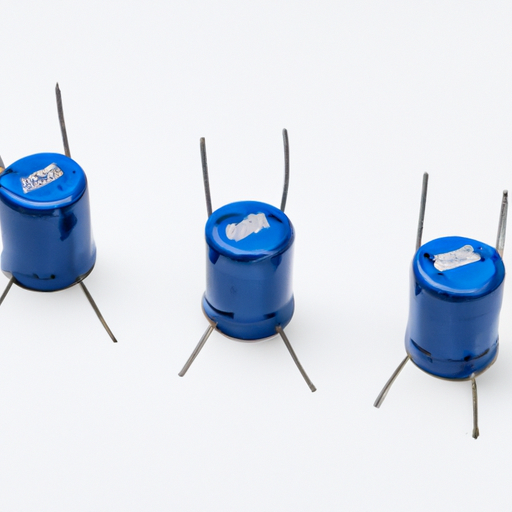

1. Electrolytic Capacitors

These capacitors are polarized and typically used for high-capacitance applications. They have a larger capacitance value but are limited to DC applications.

2. Ceramic Capacitors

Ceramic capacitors are non-polarized and widely used for their stability and reliability. They are suitable for high-frequency applications.

3. Film Capacitors

Film capacitors use a thin plastic film as the dielectric. They are known for their low ESR and high stability, making them ideal for audio and precision applications.

4. Tantalum Capacitors

Tantalum capacitors are also polarized and offer high capacitance in a small package. They are commonly used in portable electronics.

5. Supercapacitors

Supercapacitors, or ultracapacitors, can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles.

III. Key Product Features of Capacitors

A. Capacitance Value

1. Definition and Importance

The capacitance value indicates how much charge a capacitor can store. It is a critical parameter that affects the performance of electronic circuits.

2. Units of Measurement (Farads, Microfarads, etc.)

Capacitance is measured in farads (F), with common values in microfarads (µF) and picofarads (pF). The choice of capacitance value depends on the specific application requirements.

B. Voltage Rating

1. Definition and Importance

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. Exceeding this voltage can lead to failure or damage.

2. Breakdown Voltage and Safety Margins

Capacitors are typically rated with a safety margin, meaning the actual operating voltage should be significantly lower than the rated voltage to ensure reliability.

C. Tolerance

1. Definition and Importance

Tolerance refers to the allowable variation in capacitance from its nominal value. It is crucial for applications requiring precise capacitance values.

2. Common Tolerance Values

Common tolerance values include ±5%, ±10%, and ±20%, with tighter tolerances available for specialized applications.

D. Temperature Coefficient

1. Definition and Importance

The temperature coefficient indicates how capacitance changes with temperature. It is essential for applications where temperature fluctuations are expected.

2. Types of Temperature Coefficients

Common types include X7R, C0G, and Y5V, each with different stability characteristics over temperature ranges.

E. Equivalent Series Resistance (ESR)

1. Definition and Importance

ESR is the internal resistance of a capacitor that affects its performance, especially in high-frequency applications. Lower ESR values are preferred for better efficiency.

2. Impact on Performance

High ESR can lead to power loss and heat generation, impacting the overall performance of the circuit.

F. Lifetime and Reliability

1. Factors Affecting Lifetime

The lifetime of a capacitor can be influenced by factors such as temperature, voltage, and ripple current. Understanding these factors is crucial for ensuring long-term reliability.

2. Reliability Ratings and Testing

Capacitors are often rated for reliability based on testing standards, such as the MIL-PRF-39014 for military applications.

G. Size and Form Factor

1. Physical Dimensions

Capacitors come in various sizes, and the physical dimensions can impact their application in circuit design.

2. Mounting Types (Through-Hole, Surface Mount)

Capacitors can be mounted using through-hole or surface mount technology (SMT), with SMT being preferred for compact designs.

H. Dielectric Material

1. Types of Dielectric Materials

Common dielectric materials include ceramic, polyester, polypropylene, and tantalum oxide. Each material has unique properties that affect performance.

2. Impact on Performance and Applications

The choice of dielectric material influences factors such as capacitance stability, temperature coefficient, and voltage rating.

IV. Specialized Capacitor Features

A. Self-Healing Capacitors

1. Definition and Mechanism

Self-healing capacitors can recover from dielectric breakdown by isolating the damaged area, allowing them to continue functioning.

2. Applications and Benefits

These capacitors are beneficial in applications where reliability is critical, such as power supplies and audio equipment.

B. High-Frequency Performance

1. Importance in RF Applications

Capacitors designed for high-frequency performance are essential in radio frequency (RF) applications, where signal integrity is crucial.

2. Types of Capacitors Suitable for High Frequencies

Ceramic and film capacitors are often preferred for their low ESR and stable performance at high frequencies.

C. Low Leakage Current

1. Definition and Importance

Low leakage current is essential in applications where energy conservation is critical, such as in battery-operated devices.

2. Applications Requiring Low Leakage

Low leakage capacitors are commonly used in timing circuits and energy storage systems.

D. Environmental Considerations

1. RoHS Compliance

Many manufacturers produce capacitors that comply with the Restriction of Hazardous Substances (RoHS) directive, ensuring they are free from harmful materials.

2. Biodegradable Options

With increasing environmental awareness, some manufacturers are exploring biodegradable capacitor options to reduce electronic waste.

V. Applications of Capacitors

A. Power Supply Filtering

Capacitors are widely used in power supply circuits to smooth out voltage fluctuations and provide stable power to electronic devices.

B. Signal Coupling and Decoupling

In audio and communication circuits, capacitors are used to couple and decouple signals, ensuring clear transmission without interference.

C. Timing Circuits

Capacitors are essential in timing circuits, where they work with resistors to create time delays in various applications.

D. Energy Storage Systems

Supercapacitors and traditional capacitors are used in energy storage systems, providing quick bursts of energy when needed.

E. Audio Equipment

In audio applications, capacitors are used for filtering and coupling signals, enhancing sound quality and performance.

F. Automotive Applications

Capacitors are used in automotive electronics for various functions, including power management, signal processing, and energy storage.

VI. Conclusion

A. Summary of Key Features

Capacitors are versatile components with various features, including capacitance value, voltage rating, tolerance, and specialized characteristics that cater to different applications.

B. Importance of Selecting the Right Capacitor

Choosing the right capacitor is crucial for ensuring optimal performance and reliability in electronic circuits. Understanding the key features and specifications helps engineers make informed decisions.

C. Future Trends in Capacitor Technology

As technology advances, we can expect innovations in capacitor design, including improved materials, enhanced performance, and environmentally friendly options.

VII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Standards

- MIL-PRF-39014: Military Specification for Capacitors

- IEC 60384: Standards for Fixed Capacitors

C. Manufacturer Specifications

- Datasheets from leading capacitor manufacturers such as Vishay, KEMET, and Panasonic.

---

This blog post provides a comprehensive overview of the product features of capacitors, highlighting their importance in electronic circuits and various applications. Understanding these features is essential for anyone involved in electronics design and engineering.