How to Choose an Off-the-Shelf Thermal Resistor

I. Introduction

Thermal resistors, also known as thermistors, are crucial components in a wide range of electronic applications. They are temperature-sensitive resistors that change their resistance based on temperature variations. This property makes them invaluable for temperature sensing, circuit protection, and various other applications. In this guide, we will explore how to choose the right off-the-shelf thermal resistor for your specific needs, ensuring optimal performance and reliability in your projects.

II. Understanding Thermal Resistors

A. What is a Thermal Resistor?

A thermal resistor is a type of resistor whose resistance varies significantly with temperature. The two main types of thermal resistors are:

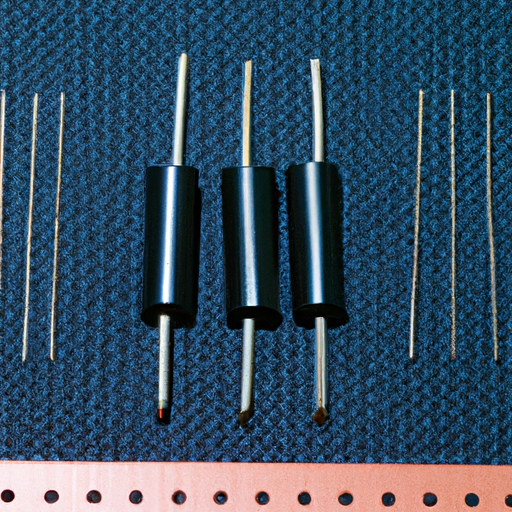

1. **Negative Temperature Coefficient (NTC) Thermistors**: These resistors decrease in resistance as temperature increases. They are commonly used for temperature sensing and inrush current limiting.

2. **Positive Temperature Coefficient (PTC) Thermistors**: These resistors increase in resistance as temperature rises. They are often used for overcurrent protection and self-regulating heating applications.

B. Key Parameters of Thermal Resistors

When selecting a thermal resistor, several key parameters must be considered:

1. **Resistance Value**: This is the resistance at a specified temperature, usually 25°C. It is essential to choose a resistance value that fits your application requirements.

2. **Temperature Coefficient**: This indicates how much the resistance changes with temperature. It is crucial for applications requiring precise temperature measurements.

3. **Tolerance**: This parameter defines the allowable deviation from the specified resistance value. A lower tolerance indicates higher accuracy.

4. **Power Rating**: This is the maximum power the resistor can dissipate without damage. It is vital to ensure that the power rating meets the demands of your application.

5. **Response Time**: This refers to how quickly the thermal resistor can respond to temperature changes. Faster response times are essential in applications requiring real-time monitoring.

III. Applications of Thermal Resistors

A. Common Applications in Electronics

Thermal resistors are widely used in various electronic applications, including:

1. **Temperature Sensing**: NTC thermistors are commonly used in temperature measurement devices, such as digital thermometers and HVAC systems.

2. **Circuit Protection**: PTC thermistors are used to protect circuits from overcurrent conditions, acting as resettable fuses.

3. **HVAC Systems**: Thermal resistors help regulate temperature in heating, ventilation, and air conditioning systems, ensuring optimal performance and energy efficiency.

B. Specialized Applications

In addition to common applications, thermal resistors are also used in specialized fields:

1. **Automotive**: They are used in engine management systems to monitor temperature and ensure optimal performance.

2. **Medical Devices**: Thermal resistors play a critical role in medical equipment, such as patient monitoring systems and incubators, where precise temperature control is vital.

3. **Industrial Equipment**: In industrial settings, thermal resistors are used for temperature monitoring and control in processes such as manufacturing and chemical processing.

IV. Factors to Consider When Choosing a Thermal Resistor

A. Application Requirements

When selecting a thermal resistor, consider the specific requirements of your application:

1. **Operating Temperature Range**: Ensure that the thermal resistor can operate effectively within the temperature range of your application.

2. **Environmental Conditions**: Consider factors such as humidity, vibration, and exposure to chemicals, which may affect the performance of the thermal resistor.

B. Electrical Specifications

Evaluate the electrical specifications to ensure compatibility with your circuit:

1. **Voltage and Current Ratings**: Ensure that the thermal resistor can handle the voltage and current levels in your application.

2. **Power Dissipation**: Choose a thermal resistor with an appropriate power rating to prevent overheating and potential failure.

C. Physical Characteristics

The physical characteristics of the thermal resistor are also important:

1. **Size and Form Factor**: Consider the available space in your design and choose a thermal resistor that fits.

2. **Mounting Options**: Thermal resistors come in various mounting styles, including through-hole and surface mount. Choose the one that best suits your assembly process.

D. Performance Characteristics

Finally, consider the performance characteristics of the thermal resistor:

1. **Response Time and Sensitivity**: For applications requiring quick temperature changes, select a thermal resistor with a fast response time and high sensitivity.

2. **Stability and Reliability**: Look for thermal resistors with a proven track record of stability and reliability in your specific application environment.

V. Evaluating Manufacturer Specifications

A. Understanding Datasheets

Manufacturer datasheets provide essential information about thermal resistors. Key specifications to look for include:

1. **Resistance vs. Temperature Characteristics**: This graph shows how resistance changes with temperature, helping you understand the thermal behavior of the resistor.

2. **Tolerance and Power Ratings**: Ensure that the thermal resistor meets your application’s tolerance and power requirements.

B. Comparing Different Manufacturers

When choosing a thermal resistor, consider the following factors:

1. **Quality and Reputation**: Research manufacturers to find those with a reputation for producing high-quality thermal resistors.

2. **Availability and Lead Times**: Ensure that the thermal resistors you need are readily available and can be delivered within your project timeline.

3. **Customer Support and Warranty**: Choose manufacturers that offer reliable customer support and warranty options for their products.

VI. Cost Considerations

A. Budgeting for Thermal Resistors

When budgeting for thermal resistors, consider the following:

1. **Cost vs. Performance Trade-offs**: While it may be tempting to choose the cheapest option, consider the long-term performance and reliability of the thermal resistor.

2. **Bulk Purchasing Options**: If you require multiple thermal resistors, inquire about bulk purchasing options to reduce costs.

B. Long-term Cost Implications

Consider the long-term implications of your choice:

1. **Reliability and Failure Rates**: Investing in high-quality thermal resistors can reduce the likelihood of failures and associated costs.

2. **Maintenance and Replacement Costs**: Factor in the costs of maintenance and potential replacements when evaluating your options.

VII. Testing and Validation

A. Importance of Testing Thermal Resistors

Testing thermal resistors is crucial to ensure they meet your application requirements. Proper testing can help identify any potential issues before deployment.

B. Methods for Testing Performance

There are several methods for testing thermal resistors:

1. **Bench Testing**: Conduct controlled tests in a laboratory setting to evaluate the thermal resistor's performance under various conditions.

2. **In-Circuit Testing**: Test the thermal resistor within the actual circuit to assess its performance in real-world conditions.

C. Validating Against Application Requirements

After testing, validate the thermal resistor's performance against your application requirements to ensure it meets all necessary specifications.

VIII. Conclusion

Choosing the right off-the-shelf thermal resistor is a critical step in ensuring the success of your electronic projects. By understanding the different types of thermal resistors, their key parameters, and the factors to consider during selection, you can make informed decisions that lead to optimal performance and reliability. Remember to conduct thorough research, evaluate manufacturer specifications, and test your chosen thermal resistors to ensure they meet your application needs. The right thermal resistor can make all the difference in achieving your project goals.

IX. References

A. Suggested readings and resources

B. Manufacturer websites and datasheets

C. Industry standards and guidelines

By following this guide, you will be well-equipped to choose the right thermal resistor for your specific applications, ensuring that your projects are successful and efficient.